FutureChocolateMLK

Brilliant_Rock

- Joined

- Mar 11, 2018

- Messages

- 1,072

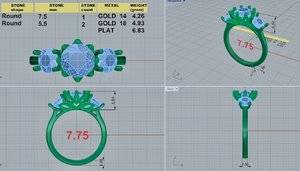

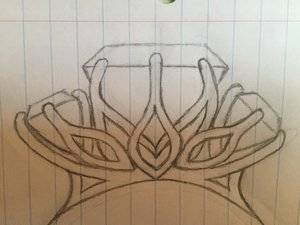

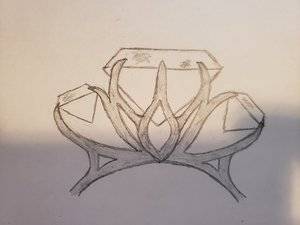

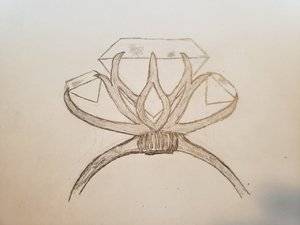

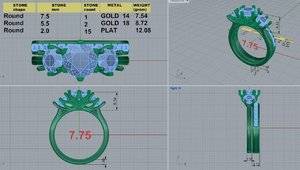

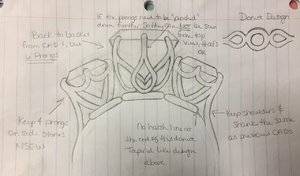

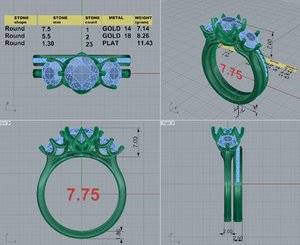

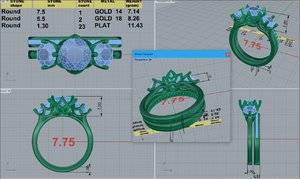

Hey everyone! This is my first custom ring so be gentle. Lol! I told him I love the shank and shoulders but the center stone needs to be 6 prong instead of 8. Somehow the “leaves” look out of place too. I’d like them to either be modified to be prongs for the side stones, or eliminated or changed somehow. I also want the basket to follow the lines of the pavilion instead of bulging out like a cup. I don’t want to be able to see any of the basket from above where it changes the look of the stone to be more like a flower.

Hey everyone! This is my first custom ring so be gentle. Lol! I told him I love the shank and shoulders but the center stone needs to be 6 prong instead of 8. Somehow the “leaves” look out of place too. I’d like them to either be modified to be prongs for the side stones, or eliminated or changed somehow. I also want the basket to follow the lines of the pavilion instead of bulging out like a cup. I don’t want to be able to see any of the basket from above where it changes the look of the stone to be more like a flower.I need expert help from PS’ers!!

300x240.png)