- Joined

- Oct 21, 2004

- Messages

- 5,096

I doubt it as it was a hypothetical question only..., not a personal enquiry...Date: 6/13/2008 1:28:36 PM

Author: EEFranklin

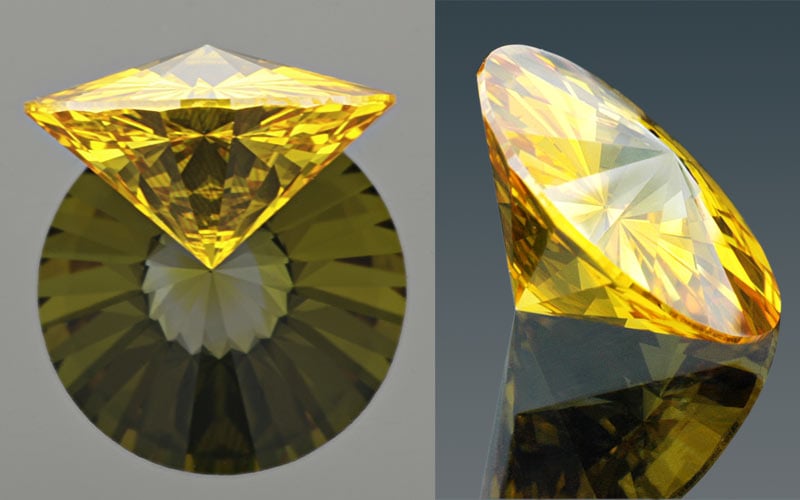

Yes, this follows what Clark was saying, and again, that picture is unaltered, as they come out of the machine.Date: 6/13/2008 6:51:03 AM

Author: DiaGem

Thanks Eric...,

The surface of the blue synthetic rough seems very smooth..., it actually seems *as* it have been polished..., is that the outcome and sign of the ''regular and consistent growth'' which Clark McEwen said/wrote?

Could be beautiful enough to leave untouched...

That is the only picture of rough I have available. Clark did post a picture of his yellow rough over here. The two colors primarily grow in each of the two respective shapes shown in ours and Clark''s pictures.Could you please post images of other examples of different shapes/structured rough? When you get some?

Did you ever witness a growth resulting in a perfect octahedron? Is it possible even?

I think this is beyond the educational scope of the forum. D.NEA only handles the finished product and doesn''t offer rough to anyone. You could contact Alexei offline and discuss this further with him.Now..., I have a hypothetical question...

If a potential client wants to acquire synthetic rough material ''only'' for the use of specialty type cuts..., is/will there be possibility? Presuming we are talking about a type of transaction that will be based on transparency and ethical behaviour!

But I think if we learn about the different marketing techniques between MMD''s and ND''s (Natural Diamonds) is certainly educational...

Since unique is becoming a greater demand these day''s..., I would figure a lot of potential lies in serving the needs of innovative cutters that think "out-side the box"

Hope you can share my vision...

300x240.png)