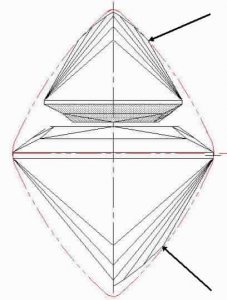

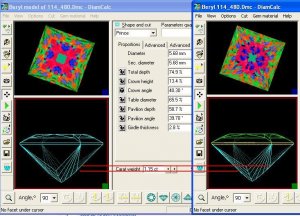

. Here's Fig.1 of the article turned for direct side view (some lines on left are missing because they were removed from wire-frame drawing for the other illustration).

. Note the closeness of 'point P'; I saw this sticking out of the crystal in an OGI demonstration. I think it can be a problem if radial dimension to 'point P' is too great or if side angle Pav1 is too steep.

. Red outline is projection of diagonals and so represents shape at corners. Bulge between corners does not show, so proximity of 'point P' at mid-side is not as bad as it appears here.

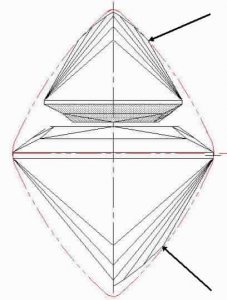

. Note the closeness of 'point P'; I saw this sticking out of the crystal in an OGI demonstration. I think it can be a problem if radial dimension to 'point P' is too great or if side angle Pav1 is too steep.

. Red outline is projection of diagonals and so represents shape at corners. Bulge between corners does not show, so proximity of 'point P' at mid-side is not as bad as it appears here.

300x240.png)