Fine jewelry settings are created from precious metals. This article addresses some important information about gold, white gold, rhodium plating and nickel allergies, as well as covering fine distinctions between common platinum alloys. Many alloys exist and new ones are constantly being developed. Here is an overview of some of the most common encountered in the crafting of jewelry

With grateful acknowledgment to the metalsmiths and craftsmen of Whiteflash

1. GOLD

Gold is popular because it can be worked into almost any shape. Yellow gold jewelry of 18K and above does not tarnish and rarely causes problems for people with skin irritations. White Gold is popular for its appearance and price point compared to platinum alloys.

Technically

there is no such thing as ‘White Gold.’ Gold can be lightened by

combining it with light metals but we plate all WG pieces with Rhodium;

a member of the platinum family and the whitest precious metal after

silver. This rhodium plating creates a hard skin with good resistance.

Over time plating may wear through. Re-plating is a fairly simple

process, depending on the condition of the piece. In most cases this

will be done approximately as often as a platinum ring requires

re-polishing, although a fine plating job may last longer than a polish

on platinum due to the superior hardness of rhodium.

COMMON GOLD ALLOYS

24K gold (100% pure gold) does not work well for jewelry because it is too soft. A more durable option is 18K gold, which is 75% pure gold. It has the richness of 24K gold where some of the less pure alloys may not.

Identification

18K gold is the most recognized global standard and will be marked ’18K’ in the USA and ‘750’ in Europe.

1. 18K Yellow Gold

- 75% Gold, alloyed with Copper, Silver, Zinc and/or Cobalt

- Does not require plating

- + Very workable

- + Rarely causes skin irritation

- – Will wear down, but over a long period of time with heavy wear

2. 18K White Gold (nickel white gold)

- 75% Gold, alloyed with Copper, Nickel, Zinc and/or Palladium

- Requires rhodium plating and re-plating over time, depending on wear

- + Less workable, less ductile

- – Causes skin irritation for people with nickel allergies

- – Will wear down over a long period of time

3. 18K Palladium White Gold

- 75% Gold, 25% Palladium

- Requires rhodium plating and re-plating over time, depending on wear

- + Very workable

- + Rarely, if ever, causes skin irritation

- – Will wear down over a long period of time

- – More expensive than 18K nickel WG

Comparison Photos

- 18K yellow gold

- 18K white gold, rhodium plated

- 18K palladium white gold, not plated

2. PLATINUM

Platinum is a versatile, eternal metal. It does not fade or tarnish and is ideal for those with sensitive skin because it is hypoallergenic. It is the safest, most suitable and versatile metal for durably setting any kind of gemstone.

Platinum’s density gives it a unique quality. When platinum scratches none of the volume is lost, the metal is merely displaced as ridges are raised on the edge of the scratch. As platinum is worn it develops a patina-like appearance. It can be polished again and again because this is just moving the metal around, not wearing it down. Other precious metals lose material over time. Gold prongs wear down and rings can get thinner with wear. Platinum prongs bend but rarely break and do not wear down.

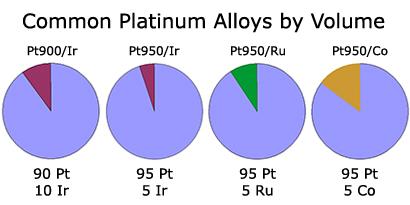

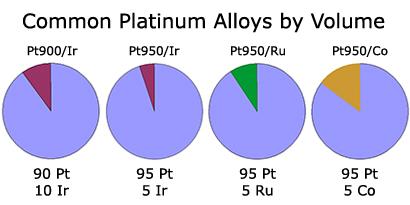

COMMON PLATINUM ALLOYS

There are 4 platinum alloys commonly used in the USA.

- Pt900/Ir = 900 parts platinum, 100 parts Iridium

- Pt950/Ir = 950 parts platinum, 50 parts Iridium

- Pt950/Ru = 950 parts platinum, 50 parts Ruthenium

- Pt950/Co = 950 parts platinum, 50 parts Cobalt

A Common Misunderstanding

When people hear Pt950 described as 95% platinum they assume that means 95% by volume. It doesn’t. The percentage is by weight. Platinum is the heaviest of these metals. Therefore, it will require more than 5% by volume of a lighter metal to match platinum by 5% in weight. This misunderstanding is merely academic information that may be of interest to some people.

Atomic Weights

- Platinum: 195.078

- Iridium: 192.217

- Ruthenium: 101.070

- Cobalt: 058.933

Identification

- 95% platinum is the world standard, marked 950 plat in country of origin

- 90% platinum is a popular and traditional USA standard, marked 900Pt

- 50%-90% platinum may be marked Plat in other countries, but only 950 platinum can be marked Plat in the USA

Alloy Comparisons

Pt900/Ir (900 parts platinum, 100 parts Iridium) is a good hard alloy. A great compromise between relative hardness for easier polish it has excellent white color and is still quite malleable. It is excellent for both casting and handmade work. Less pressure is required to set gemstones than with harder alloys. It is resistant to scratching & bending and over time is very resistant to signs of wear.

Pt950/Ir (950 parts platinum, 50 parts Iridium) is a good medium-hard alloy which is malleable and well-suited for bench work. Good for casting and excellent for handmade pieces, it is the best choice for soft or fragile gem setting. The greater softness requires a longer polishing process. It is less scratch and bend resistant than harder alloys but holds a stone better if an impact occurs; like a shock absorber. Over time it is very resistant to signs of wear.

Pt950/Ru (950 parts platinum, 50 parts Ruthenium) is very hard. It has the highest melting temperature of all platinum alloys and is difficult to cast. Darker gray in color than platinum-iridium, it is less malleable, hard to solder and weld and hard to burnish. Bench workers find it tough on burs, files and drills. Some setters recommend it for diamonds only, since more pressure must be imposed on gemstones during the setting process. It is extremely scratch & bend-resistant and extremely resistant to signs of wear over time.

Pt950/Co (950 parts platinum, 50 parts Cobalt) is moderately hard. With the lowest flow point of these alloys it is good for even, dense castings of finely detailed pieces or filigree but not for work by hand. This alloy tarnishes when heated so it needs flux and pickling after soldering just like gold, unlike other platinum alloys. Since Cobalt is a ferrous metal, not from the platinum group, its scraps must be kept separate from other platinum scraps. It takes a fast polish but finishes darker gray than iridium. It requires moderate pressure on gemstones during the setting process. Bench workers find it more “gold-like” and easy on the tools. It wears quite well over time.

Platinum/Iridium is the whitest and the softest alloy, excellent for production and setting. It solders and welds better than other platinum alloys. In the USA Pt900/Ir is a popular and traditional standard. The global platinum standard is 95% by weight, so manufacturers with a global clientele use Pt950/Ir.

The Most Important Element

The way the piece was formed, the heat treatments, welding and soldering applied and the skill of the craftsmen involved are all as critical to the final product as the alloy itself. Seasoned craftsmen and smiths may develop a favorite based on personal experience but no platinum alloy is “better” or “worse” than the others. In fact, the most important element is the way the piece is cared for. How the wearer cares for the ring will be more significant to how it holds up over time than any other factor. The skill level of the craftsman is equally important. Whatever alloy is used comes in far behind the first two considerations.

Platinum is used in industry and medicine as well as for fine jewelry applications. In all cases we feel platinum is a wonderful choice for a lifetime of wear.

Comparison Photos

- Platinum-iridium

- Platinum-ruthenium

- Platinum-cobalt

3. HARDNESS AND DURABILITY

In discussions about precious metals people often confuse hardness with strength, but they are not the same.

Hardness = HV

Often referred to as “scratch resistance,” hardness is measured using the Vickers Hardness scale. This tests the hardness of a metal by pushing a pointed object into the surface with a specified load and gauging penetration.

Durability = PSI

Tensile strength, or durability is measured in pounds per square inch.

Comparisons

- 18K Gold = 125 HV…29,000 PSI

- Pt900/Ir = 110HV…55,000 PSI

- Pt950/Ir = 80HV…40,000 PSI

- Pt950/Ru = 130HV…66,000 PSI

- Pt950/Co = 135HV…64,000 PSI

Gold is harder than some platinum alloys and will resist scratches better. Platinum is almost twice as durable as gold, is more ductile has much greater longevity. For the body of the piece the differences are not critical. For the prongs they have implications: For instance, white gold prongs will break. Yellow gold prongs will bend more, as will platinum, but platinum prongs are more durable over time.

4. OTHER ALLOYS

The alloys above are most common in our experience, but many other alloys exist.

Colored gold alloys range from 8 to 22K in gold content and can be produced in color shades such as rose and red (greater copper content), green (more silver) and even purple (gold-aluminum).

White gold alloys using chromium and iron instead of nickel have been developed to address the problem of nickel allergies.

Stuller’s new X-1 14K white gold alloy has good whiteness and passes the EU Nickel Release tests. It is yet untested for longevity and durability.

950 Palladium is similar to platinum alloys; 95% palladium alloyed with 5% ruthenium by weight. Like platinum alloys it only requires occasional repolish. However, it is not as white as more common Platinum/Iridium alloys and is priced similarly and not many people work in it.

Plat/S+ is another 950 platinum alloy offered by Hoover & Strong (the remaining ingredients are proprietary). Harder than other traditional platinum alloys, it was developed by the late Steven Kretchmer, who introduced tension-set rings in the USA, under the name SK Platinum.

950 PlatOro is 95% platinum and 5% gold by weight. Also from Hoover & Strong, it has high flow characteristics which keep porosity to a minimum. It is ductile, with similar hardness to Pt950/Ru.

New alloys are constantly being developed. As with precious stones, the variety of offerings and options available to the consumer in precious metals and alloys reflects the wide variety of taste among enthusiasts.

by John Pollard

Director of Education for Whiteflash 2004-2008

Whiteflash Inc.