BAS2348

Rough_Rock

- Joined

- Aug 4, 2015

- Messages

- 63

Hi again everyone,

So I have a bit of a rant to get off my chest. I purchased a BGD cushion and am currently having it set with David Klass, when I sent my very first email (back with the idea was to get a 3 stone) I included at the end the abnormality that comes along with BGD cushions in terms of how they're measured, I had hoped that Amy or David had read that little tidbit to avoid any misunderstandings with our stone. Last week we agreed on the final CADs, and I approved them for casting, today I got an email from him:

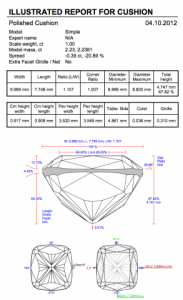

"I am having a slight issue with your center stone. Your ring was cast and when we fit the stone it would not fit. The .698ct weight is correct, and the stone is laser inscribed with the same number on the AGS certification. The mm measurements on the certificate and diamond paper say (6.03mm x 5.19mm x 3.49mm). This stone measures 5.19mm x 5.17mm x 3.46mm. When your stone arrived I checked the diamond weight but I have never had an AGS certificate differ from an actual diamond measurements. You need to contact Brian Gavin to figure out the mistake to get the correct certification. I need to recast the ring to fit correctly. Thanks David"

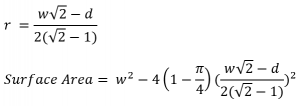

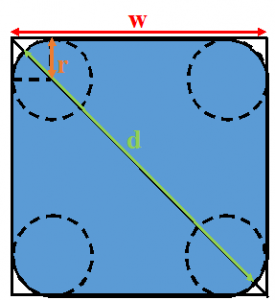

I feel absolutely terrible and embarrassed that I put them through all of this simply because of the technicality of BGD measurements. I went back to the CADs and noticed that all of them read 6.03 mm for LENGTH, something I SHOULD have corrected but I did not because I assumed David measured the stone when he received it. Can anyone please explain to me WHY AGS does not include an excerpt about the diagonal measurements on BGD's reports? Considering how different it is, I would think it would be a critical piece of information to include on their reports. I feel like this isn't the first time this has happened, and I am mortified that David has to start all over again on our setting.

So I have a bit of a rant to get off my chest. I purchased a BGD cushion and am currently having it set with David Klass, when I sent my very first email (back with the idea was to get a 3 stone) I included at the end the abnormality that comes along with BGD cushions in terms of how they're measured, I had hoped that Amy or David had read that little tidbit to avoid any misunderstandings with our stone. Last week we agreed on the final CADs, and I approved them for casting, today I got an email from him:

"I am having a slight issue with your center stone. Your ring was cast and when we fit the stone it would not fit. The .698ct weight is correct, and the stone is laser inscribed with the same number on the AGS certification. The mm measurements on the certificate and diamond paper say (6.03mm x 5.19mm x 3.49mm). This stone measures 5.19mm x 5.17mm x 3.46mm. When your stone arrived I checked the diamond weight but I have never had an AGS certificate differ from an actual diamond measurements. You need to contact Brian Gavin to figure out the mistake to get the correct certification. I need to recast the ring to fit correctly. Thanks David"

I feel absolutely terrible and embarrassed that I put them through all of this simply because of the technicality of BGD measurements. I went back to the CADs and noticed that all of them read 6.03 mm for LENGTH, something I SHOULD have corrected but I did not because I assumed David measured the stone when he received it. Can anyone please explain to me WHY AGS does not include an excerpt about the diagonal measurements on BGD's reports? Considering how different it is, I would think it would be a critical piece of information to include on their reports. I feel like this isn't the first time this has happened, and I am mortified that David has to start all over again on our setting.

300x240.png)