Vizsla Girl

Rough_Rock

- Joined

- Jun 27, 2008

- Messages

- 42

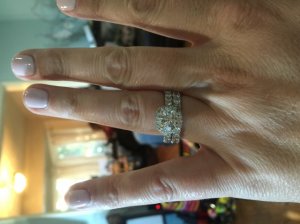

Hello group. I have picked my stone, 2.24 carat RB and am now working on the CAD. I asked for this setting, but larger stones with the shank as pictured first...

And the CAD is as outlined in the second picture. Am I just totally clueless when it comes to CADs? I am not ready to approve such a thing when I asked for a RB stone in a cushion halo, with falling edge, and no gaps/spaces/ blank spaces around the stone and the halo. I have been told they 'need room' to fine tune and all and that the final piece will only be 2.2 mm tall and 3mm wide but holy cow this looks horrific to me! Look at the gaps around the halo... Not to mention the awkward spaces on the shank between the diamonds? What am I missing here?

And the CAD is as outlined in the second picture. Am I just totally clueless when it comes to CADs? I am not ready to approve such a thing when I asked for a RB stone in a cushion halo, with falling edge, and no gaps/spaces/ blank spaces around the stone and the halo. I have been told they 'need room' to fine tune and all and that the final piece will only be 2.2 mm tall and 3mm wide but holy cow this looks horrific to me! Look at the gaps around the halo... Not to mention the awkward spaces on the shank between the diamonds? What am I missing here?

300x240.png)