TooMuchInformation

Rough_Rock

- Joined

- Oct 24, 2003

- Messages

- 96

Alright, not too sure if this is the right forum for this question or not (didn''t find any other ones that seems particularly more appropriate), so if I''m in the wrong place, let me know and I''ll move my post elsewhere.

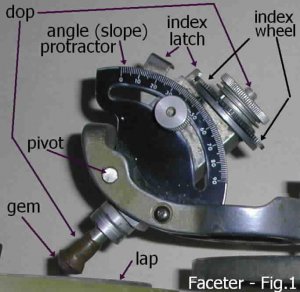

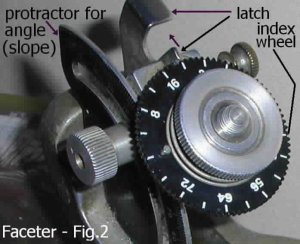

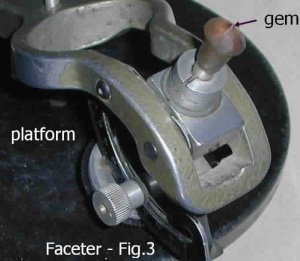

I''m looking to find someone that goes gem faceting / cutting. Wondering what tools they use, how they went about learning, and how difficult the process is to learn.

After purchasing an engagement ring for my now fiance, I''m totally obsessed with gems of all sorts; I just can''t read / learn enough about them!

I''m looking to find someone that goes gem faceting / cutting. Wondering what tools they use, how they went about learning, and how difficult the process is to learn.

After purchasing an engagement ring for my now fiance, I''m totally obsessed with gems of all sorts; I just can''t read / learn enough about them!

300x240.png)