- Joined

- Aug 15, 2000

- Messages

- 18,943

In this article https://member.rapnet.com/news/News...8526&RDRIssueID=0&ArticleTitle=The+Last+Facet

The Last Facet

IF THE JEWELRY INDUSTRY DOESN’T DO SOMETHING, THERE MIGHT NOT BE ANY DIAMOND CUTTERS LEFT IN THE U.S. 15 YEARS FROM NOW. IS THERE ANYTHING THAT CAN BE DONE — AND IS THERE ANY REASON TO DO IT

Several cutters lament the issue.

But they missed the real reason: not keeping up with technology.

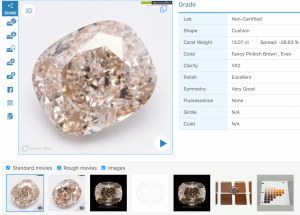

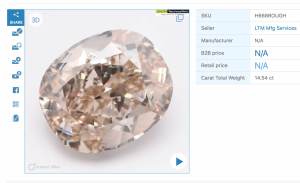

Here is an example in a 8 minute video showing how diamonds are polished in the state of the art LTM factory in Surat India:

All the people interviewed missed the point. The industry moved with the technology and the traditional US cutters never kept up.

Sarine, OctoNus / Lexus, OGI and other technology companies make almost all their sales in India.and other "low wage" centers. The idea that one person takes a rough and produces polished moved to 20 or more specialists working on each rough stone all connected to computer databases. If you estimate the cost of wages plus depreciation of technology it probably costs more to polish in India than New York.

Its more or less the same in Antwerp and othe traditional centers except for the few companies using state of the art hi tech to cut and polish the rare very large stones that are being found by innovative small miners and many of those bought old De Beers mines and introduced Xray scanning of pre and partially crushed ore.

So if anyone wants to manufacture polished anywhere in the world, low wages are just a part of the input costs. Perhaps India's main point of difference is the million young engineers graduating each year?

The Last Facet

IF THE JEWELRY INDUSTRY DOESN’T DO SOMETHING, THERE MIGHT NOT BE ANY DIAMOND CUTTERS LEFT IN THE U.S. 15 YEARS FROM NOW. IS THERE ANYTHING THAT CAN BE DONE — AND IS THERE ANY REASON TO DO IT

Several cutters lament the issue.

But they missed the real reason: not keeping up with technology.

Here is an example in a 8 minute video showing how diamonds are polished in the state of the art LTM factory in Surat India:

All the people interviewed missed the point. The industry moved with the technology and the traditional US cutters never kept up.

Sarine, OctoNus / Lexus, OGI and other technology companies make almost all their sales in India.and other "low wage" centers. The idea that one person takes a rough and produces polished moved to 20 or more specialists working on each rough stone all connected to computer databases. If you estimate the cost of wages plus depreciation of technology it probably costs more to polish in India than New York.

Its more or less the same in Antwerp and othe traditional centers except for the few companies using state of the art hi tech to cut and polish the rare very large stones that are being found by innovative small miners and many of those bought old De Beers mines and introduced Xray scanning of pre and partially crushed ore.

So if anyone wants to manufacture polished anywhere in the world, low wages are just a part of the input costs. Perhaps India's main point of difference is the million young engineers graduating each year?

300x240.png)