I have looked at many, many local jewelers for the "perfect" ring, but have not found it. I have it envisioned the perfect ring, and have accurately drawn it in sketches, and taken photos of the closest rings I have found. I need the jeweler to design the ring and supply the sidestones. There are 2 local jewelers in town, 1 quoting $1250 total, 1 quoting $1850 (talked down from $2150) total. The $1250 will be hand carved from a block of wax, and the $1850 would be designed in CAD. I won''t be in town to see in-person, so it would be e-mailed photos or e-mailed CAD images/renders. Both jewelers say they can do the ring exactly how I have drawn (top and side view skethces supplied as well). $600 is a lot of money, but the CAD jeweler states they can get the precision much better than hand-made! I''m lost, what do you think is best?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Custom Engagement Ring: Hand Carved vs. CAD?

- Thread starter pauleroni

- Start date

- Joined

- Nov 19, 2003

- Messages

- 1,290

Precision ? What sort of precision do you need ? CAD is great and the models being made from it are definitely very precise, but that is NOT the advantage of CAD. The advantage of CAD, for you, lies in the fact that you get to see an accurate virtual model of the piece prior to authorizing its fabrication AND that it is easy to make changes if you do decide to make some. With a hand carved wax you still get to see pictures prior to committing to fabrication, but the model is harder to change, (plus if anything messes up during casting the entire model needs to be remade...not a problem to you). A good wax modeler can make a piece that''s every bit as good as a CAD modeled ring and, unless you have a really unusually shaped piece, there is no real advantage, to you, between the two processes. (The real advantage of CAD is on the jewelers end, since anyone with a little training can make an acceptable CAD model, while good wax carving takes some inherent skill, practice and time. This makes CAD modeling faster and less expensive for the jeweler...no idea why it would cost more to use this process in your case).

Thanks for your reply. The more expensive (CAD jeweler) originally quoted me $1350 3-4 months ago. They say the increase in price (1350 to 2150 talked down to 1850) is largely due to the increase of metal price from then to now ("at an all time high") (some due to increase in required labor). Roughly how much would the metal alone cost of a 14k white gold ring (simple 3-stone ring)? $500 price increase?

- Joined

- Nov 19, 2003

- Messages

- 1,290

Date: 5/8/2010 8:14:29 PM

Author: pauleroni

Roughly how much would the metal alone cost of a 14k white gold ring (simple 3-stone ring)? $500 price increase?

Since I am a vendor I can''t answer that question directly. I can say though that the cost of materials on a ring of this type, in general, is about 1/3 of the total cost of the project, assuming the lower end cost that you''ve mentioned. This is for a fairly heavy ring. The other costs involved are in the time spent either carving the wax or doing the CAD work, as well as the time making the mold, casting, setting stones and finishing, (these costs are substantial as well). Overhead and profit are the things which will change dramatically from one vendor to another. Using the cost of materials as the reason for a price increase which is more than the cost of the materials doesn''t make much sense unless that price has also more than doubled. If you want to see the cost of gold over time, check out "kitco", they have gold prices listed as they have changed over the past years and months, (pick whatever detail level you''d like).

Whoever you choose, I would recommend asking the jeweler if they can make this with one of the newer "extra white" alloys that is available. Stuller makes one called X-1 and you can see some of the specs at their site. There are several other suppliers of similar alloys. They are harder to cast, (hotter cast temperatures), but never need plating with rhodium, stay white and meet all current low nickel laws.

ChunkyCushionLover

Ideal_Rock

- Joined

- Jun 21, 2009

- Messages

- 2,463

No its not justified. Personally I wouldn''t want a hand carved wax, very few can do it as well as the CAD machine. There are lots of great PS vendors that do CAD work I don''t think a simple 3 stone ring should be that expensive.Date: 5/8/2010 8:14:29 PM

Author: pauleroni

Thanks for your reply. The more expensive (CAD jeweler) originally quoted me $1350 3-4 months ago. They say the increase in price (1350 to 2150 talked down to 1850) is largely due to the increase of metal price from then to now (''at an all time high'') (some due to increase in required labor). Roughly how much would the metal alone cost of a 14k white gold ring (simple 3-stone ring)? $500 price increase?

However not even sure about 14k gold, most would use 18k around here.

- Joined

- Nov 19, 2003

- Messages

- 1,290

Date: 5/8/2010 11:24:17 PM

Author: ChunkyCushionLover

Date: 5/8/2010 8:14:29 PM

Personally I wouldn''t want a hand carved wax, very few can do it as well as the CAD machine. There are lots of great PS vendors that do CAD work

Well you know, there''s a time and a place for everything. Computer modeling is fine for things that have repetitive details or have details which are not exceptionally complex. Then you have things that are best suited for hand work. Details like faces, complex floral styles, and others really do require hand carving of wax and/or hand carving of the metalwork. CAD is a great tool and I love using it, but it''s just one tool and should not be looked at as if it is some sort of end in itself. For instance there is a lot of stuff that really can''t be done well with any casting technique and really needs to be completely hand fabricated to produce an adequate piece of jewelry. You''ve really got to have and use all of the tools, past and present, to do much of the higher quality work. Making a neat drawing is no guarantee that a piece will actually "work" regardless of how "precise" it is.

ChunkyCushionLover

Ideal_Rock

- Joined

- Jun 21, 2009

- Messages

- 2,463

Theoretically if one doesn''t think the CAD wax modeler is good enough for the design than I question whether it can be done properly with a wax at all and parts if not all should be hand fabricated. But this customer and their budget does not warrant such a high end and time consuming process and it doesn''t apply to this simple three stone design either.Date: 5/9/2010 1:13:23 AM

Author: Michael_E

Date: 5/8/2010 11:24:17 PM

Author: ChunkyCushionLover

Date: 5/8/2010 8:14:29 PM

Personally I wouldn''t want a hand carved wax, very few can do it as well as the CAD machine. There are lots of great PS vendors that do CAD work

Well you know, there''s a time and a place for everything. Computer modeling is fine for things that have repetitive details or have details which are not exceptionally complex. Then you have things that are best suited for hand work. Details like faces, complex floral styles, and others really do require hand carving of wax and/or hand carving of the metalwork. CAD is a great tool and I love using it, but it''s just one tool and should not be looked at as if it is some sort of end in itself. For instance there is a lot of stuff that really can''t be done well with any casting technique and really needs to be completely hand fabricated to produce an adequate piece of jewelry. You''ve really got to have and use all of the tools, past and present, to do much of the higher quality work. Making a neat drawing is no guarantee that a piece will actually ''work'' regardless of how ''precise'' it is.

pixley

Brilliant_Rock

- Joined

- Nov 12, 2007

- Messages

- 1,596

Hi pauleroni,Date: 5/8/2010 7:40:02 PM

Author:pauleroni

Both jewelers say they can do the ring exactly how I have drawn (top and side view skethces supplied as well). $600 is a lot of money, but the CAD jeweler states they can get the precision much better than hand-made! I''m lost, what do you think is best?

Have you had a chance to look at each jeweler''s body of work? Often they''ll have photo books to showcase their custom work. In my experience - no jeweler ever ever says they can''t do something, but if you don''t see examples of the kind of details you are looking for in their portfolio, I''d recommend waiting to find someone who is well versed in the style you''re after, and can back it up with photos.

If you''d like to post your photos or sketches, maybe we can help link you to someone who''s great at executing custom designs.

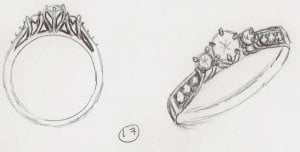

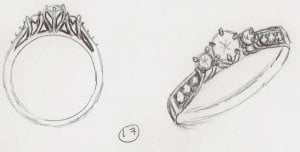

Thank you all for your replies. To help me illustrate exactly what I am looking at to get made, I have attached my sketches (ignore the "prong-like" metal pieces sticking out for the channel diamonds on the side view). Any advice on technique, price, or metal, would be greatly appreciated. I am leaning away from an online jeweler only because I would have to send my diamonds in the mail. Unless...would an online jeweler be able to make the CAD, then I bring that to a local jeweler, or would the local jeweler not be willing to cast someone elses CAD?

- Joined

- Nov 19, 2003

- Messages

- 1,290

Author: ChuckyCushionLover

Theoretically if one doesn''t think the CAD wax modeler is good enough for the design than I question whether it can be done properly with a wax at all and parts if not all should be hand fabricated. But this customer and their budget does not warrant such a high end and time consuming process and it doesn''t apply to this simple three stone design either.

This is true, but with such a large price difference, I would consider the end result more important than how it was arrived at.

I agree with Pixley in that looking at pictures of either of the competing jewelers previous work will give you a good idea of who you may want to work with. I would also say that this design would be rather easy to make with any method and CAD modeling only offers an advantage in terms of speed. Making models in wax doesn''t always mean actually carving the wax, but at times means that you use premade parts which are melted together to form an assembly. Things like round strands for prongs and beads are a good example. For this piece making the ring by hand in wax would be nearly as fast as modeling it in CAD and then you can skip the step in CAD that requires that the actual model be milled or grown. On the other hand the CAD model would be more precise, BUT that same precision doesn''t always carry over in the chain of events from modeling to mold making to casting in thin parts like prongs, so I doubt if you''d ever notice a difference. It pretty much boils down to who you''d prefer to work with and price...assuming their work is comparable.

As for shipping your diamonds, well anyone in the business for any length of time will be using independent third party insurance and you can ship on their account, (reimbursing them later). This is a requirement so that everyone gets covered financially.

- Joined

- Jul 21, 2004

- Messages

- 9,159

A significant amount of the work on this piece has to do with the final assembly, finishing and setting of the stones. The original wax, whether it’s hand done or CAD is not all that high a percentage of the work or of your budget. I agree with the above suggestion of looking at some completed work from the jewelers you are considering and choose your craftsman based on this as well as your general 'feel' for how well they understand your requirements. Look especially at the ‘fit and finish’ of the pieces. Ask them to see a piece or two from inventory that they’re proud to have made and then carefully inspect them with a magnifier. Are all the stones set securely and straight? Is it polished in all the places where you would expect it to be polished? Are the assembled parts, like the head on the center stone, soldered on securely and straight? Is it symmetrical (assuming the design calls for that)? Is there visible pitting in the casting? Is there anything about it that just looks off to you?

Most of the online jewelers who offer custom services are no more or less than a ‘regular’ jeweler who is located in someone else’s neighborhood and who is advertising to a worldwide audience. That’s a pretty easy CAD job and it’s kind of a difficult carving and I would usually expect CAD costs less, not more, on this kind of thing. This may indicate that the CAD company is expecting more work to go into the finishing steps and/or that they value their time higher than the other. I’m not sure either of these is a bad sign. Bear in mind that the cheapest craftsman is not usually the best.

I would concentrate on the final results that each jeweler produces over a discussion of how they got there.

Neil Beaty

GG(GIA) ICGA(AGS) NAJA

Professional Appraisals in Denver

Most of the online jewelers who offer custom services are no more or less than a ‘regular’ jeweler who is located in someone else’s neighborhood and who is advertising to a worldwide audience. That’s a pretty easy CAD job and it’s kind of a difficult carving and I would usually expect CAD costs less, not more, on this kind of thing. This may indicate that the CAD company is expecting more work to go into the finishing steps and/or that they value their time higher than the other. I’m not sure either of these is a bad sign. Bear in mind that the cheapest craftsman is not usually the best.

I would concentrate on the final results that each jeweler produces over a discussion of how they got there.

Neil Beaty

GG(GIA) ICGA(AGS) NAJA

Professional Appraisals in Denver

ChunkyCushionLover

Ideal_Rock

- Joined

- Jun 21, 2009

- Messages

- 2,463

I agree with you and Pixley as well, the most important part is the finishing. In this particular design the symmetry of the hearts and the spaces would be important and a little more difficult to obtain perfect symmetry with hand carving but not impossible. Unfortunately it is often quite difficult to get local jeweler''s(or any jeweler) to show you similar enough pieces so that you know how good their polish, symmetry and finishing skills are. I tried this but ended up not being able to make a well informed decision so instead I found an online jeweler who had done similar designs and I was comfortable using them. While this design is relatively simple it still requires fine finishing and I would want to this done with thin delicate pieces and thin delicate prongs and side profile pieces, the delicacy, polish and symmetry of the pieces can make or break this design.Date: 5/9/2010 2:47:58 PM

Author: Michael_E

Author: ChuckyCushionLover

Theoretically if one doesn''t think the CAD wax modeler is good enough for the design than I question whether it can be done properly with a wax at all and parts if not all should be hand fabricated. But this customer and their budget does not warrant such a high end and time consuming process and it doesn''t apply to this simple three stone design either.

This is true, but with such a large price difference, I would consider the end result more important than how it was arrived at.

I agree with Pixley in that looking at pictures of either of the competing jewelers previous work will give you a good idea of who you may want to work with. I would also say that this design would be rather easy to make with any method and CAD modeling only offers an advantage in terms of speed. Making models in wax doesn''t always mean actually carving the wax, but at times means that you use premade parts which are melted together to form an assembly. Things like round strands for prongs and beads are a good example. For this piece making the ring by hand in wax would be nearly as fast as modeling it in CAD and then you can skip the step in CAD that requires that the actual model be milled or grown. On the other hand the CAD model would be more precise, BUT that same precision doesn''t always carry over in the chain of events from modeling to mold making to casting in thin parts like prongs, so I doubt if you''d ever notice a difference. It pretty much boils down to who you''d prefer to work with and price...assuming their work is comparable.

As for shipping your diamonds, well anyone in the business for any length of time will be using independent third party insurance and you can ship on their account, (reimbursing them later). This is a requirement so that everyone gets covered financially.

pixley

Brilliant_Rock

- Joined

- Nov 12, 2007

- Messages

- 1,596

Date: 5/9/2010 3:11:23 PM

Author: denverappraiser

A significant amount of the work on this piece has to do with the final assembly, finishing and setting of the stones. The original wax, whether it’s hand done or CAD is not all that high a percentage of the work or of your budget. I agree with the above suggestion of looking at some completed work from the jewelers you are considering and choose your craftsman based on this as well as your general 'feel' for how well they understand your requirements. Look especially at the ‘fit and finish’ of the pieces. Ask them to see a piece or two from inventory that they’re proud to have made and then carefully inspect them with a magnifier. Are all the stones set securely and straight? Is it polished in all the places where you would expect it to be polished? Are the assembled parts, like the head on the center stone, soldered on securely and straight? Is it symmetrical (assuming the design calls for that)? Is there visible pitting in the casting? Is there anything about it that just looks off to you?

Most of the online jewelers who offer custom services are no more or less than a ‘regular’ jeweler who is located in someone else’s neighborhood and who is advertising to a worldwide audience. That’s a pretty easy CAD job and it’s kind of a difficult carving and I would usually expect CAD costs less, not more, on this kind of thing. This may indicate that the CAD company is expecting more work to go into the finishing steps and/or that they value their time higher than the other. I’m not sure either of these is a bad sign. Bear in mind that the cheapest craftsman is not usually the best.

I would concentrate on the final results that each jeweler produces over a discussion of how they got there.

Neil Beaty

GG(GIA) ICGA(AGS) NAJA

Professional Appraisals in Denver

Your design and your sketches are lovely, Pauleroni! Neil's given you a fantastic tip sheet (see above) to consider if you decide to go with your local jeweler. If you're open to going with an on-line vendor, I would suggest taking a look at Brian Gavin Diamonds' website. Here's a link to their three stone designs: http://www.briangavindiamonds.com/engagement-rings/three-stone/ I love the fluidity and precision of their work. You can also search their work on Pricescope and I think you'll find lots of close up images and lots of thrilled clients. It might be worth a phone call to see if they can help you bring your design to life.

This forum and all of you have been an extreme help so far! Thank you for that. I will be in touch with Brian Gavin''s company to see how they may help me.

I would prefer CAD for these reasons - 1) some of you state, for this particular design, CAD may be "better", or faster, etc. 2) I would love a copy of the CAD drawings to hold onto forever, eventually showing my gf/hope to be wife

As you have recommended, I will be going into both jewelers again to look at their previous custom rings. I will be moving soon, and wouldn''t be able to look at the ring mid-progress from the wax-only jeweler, so that does put me off. I''m also debating on trying out jewelers in my new town as well.

What I can''t fathom is an increase of $800 (before being talked down) due to "largely due to the increase of the price of metal", that concerns me. However, this jeweler states they have 6 jewelers/designers/crafters from Germany, Belgium, etc, and they have a mighty fine reputation. $600 is a lot though.

So, as Michael E as suggested, as it would come down to who I would want to work for (CAD jeweler due to me moving) and the price (wax only), I''m still torn. Hopefully the jewelers in my new town will work out great, but price is a huge factor.

ChunkyCushionLover - when you say the delicacy, polish and symmetry can make or break this design, how would I go about to ensure this part of the process is done well, other than look at their past work?

I would prefer CAD for these reasons - 1) some of you state, for this particular design, CAD may be "better", or faster, etc. 2) I would love a copy of the CAD drawings to hold onto forever, eventually showing my gf/hope to be wife

As you have recommended, I will be going into both jewelers again to look at their previous custom rings. I will be moving soon, and wouldn''t be able to look at the ring mid-progress from the wax-only jeweler, so that does put me off. I''m also debating on trying out jewelers in my new town as well.

What I can''t fathom is an increase of $800 (before being talked down) due to "largely due to the increase of the price of metal", that concerns me. However, this jeweler states they have 6 jewelers/designers/crafters from Germany, Belgium, etc, and they have a mighty fine reputation. $600 is a lot though.

So, as Michael E as suggested, as it would come down to who I would want to work for (CAD jeweler due to me moving) and the price (wax only), I''m still torn. Hopefully the jewelers in my new town will work out great, but price is a huge factor.

ChunkyCushionLover - when you say the delicacy, polish and symmetry can make or break this design, how would I go about to ensure this part of the process is done well, other than look at their past work?

CharmyPoo

Ideal_Rock

- Joined

- Dec 10, 2004

- Messages

- 7,007

I don't have much to add but just a thought. Since you are moving, is there a benefit of going with one of the two jewelers you selected? It might be easier to go with a company like BGD or Whiteflash or Michael E where you can easily see tons of pictures and examples of the finished product right here on PS. There are many happy customers here which helps in terms of making your due deligence work a fair bit easier. They also both do CAD and CAST which I believe you decided is the way to go.

ChunkyCushionLover

Ideal_Rock

- Joined

- Jun 21, 2009

- Messages

- 2,463

No other way unfrotunately that is why it is very hard to do in B&M stores and a little easier with known PS vendors with many past customers posting in the Show Me The Bling section.Date: 5/9/2010 10:01:59 PM

Author: pauleroni

This forum and all of you have been an extreme help so far! Thank you for that. I will be in touch with Brian Gavin''s company to see how they may help me.

I would prefer CAD for these reasons - 1) some of you state, for this particular design, CAD may be ''better'', or faster, etc. 2) I would love a copy of the CAD drawings to hold onto forever, eventually showing my gf/hope to be wife

As you have recommended, I will be going into both jewelers again to look at their previous custom rings. I will be moving soon, and wouldn''t be able to look at the ring mid-progress from the wax-only jeweler, so that does put me off. I''m also debating on trying out jewelers in my new town as well.

What I can''t fathom is an increase of $800 (before being talked down) due to ''largely due to the increase of the price of metal'', that concerns me. However, this jeweler states they have 6 jewelers/designers/crafters from Germany, Belgium, etc, and they have a mighty fine reputation. $600 is a lot though.

So, as Michael E as suggested, as it would come down to who I would want to work for (CAD jeweler due to me moving) and the price (wax only), I''m still torn. Hopefully the jewelers in my new town will work out great, but price is a huge factor.

ChunkyCushionLover - when you say the delicacy, polish and symmetry can make or break this design, how would I go about to ensure this part of the process is done well, other than look at their past work?

rhbgirl24

Ideal_Rock

- Joined

- Feb 6, 2009

- Messages

- 2,181

I agree with everyone here. My ring is custom, first ring was hand done - hated that it wasn''t 100% precise and so did my fiance. Fast forward through a VERY long story and a new jeweler who does awesome CAD work and now its PERFECT!

But, like everyone said, my jeweler was as precise and had just as precise attention to detail in the finishing work as well as the CAD start....

But, like everyone said, my jeweler was as precise and had just as precise attention to detail in the finishing work as well as the CAD start....

Date: 5/13/2010 8:38:08 AM

Author: rhbgirl24

I agree with everyone here. My ring is custom, first ring was hand done - hated that it wasn't 100% precise and so did my fiance. Fast forward through a VERY long story and a new jeweler who does awesome CAD work and now its PERFECT!

But, like everyone said, my jeweler was as precise and had just as precise attention to detail in the finishing work as well as the CAD start....

Would you mind sharing with what jeweler you went to, if online? I have contacted BG, Whiteflash, and Michael E at the Gem Shoppe for quotes, to name a few. Or, would you be able to recommend a different online jeweler?

ChunkyCushionLover

Ideal_Rock

- Joined

- Jun 21, 2009

- Messages

- 2,463

ERD does excellent CAD work and more refined finishing than some of the others mentioned. His jeweler created all of our rings except the mokume gane men's ring thread here.Date: 5/13/2010 12:07:42 PM

Author: pauleroni

Date: 5/13/2010 8:38:08 AM

Author: rhbgirl24

I agree with everyone here. My ring is custom, first ring was hand done - hated that it wasn't 100% precise and so did my fiance. Fast forward through a VERY long story and a new jeweler who does awesome CAD work and now its PERFECT!

But, like everyone said, my jeweler was as precise and had just as precise attention to detail in the finishing work as well as the CAD start....

Would you mind sharing with what jeweler you went to, if online? I have contacted BG, Whiteflash, and Michael E at the Gem Shoppe for quotes, to name a few. Or, would you be able to recommend a different online jeweler?

While they are not up to the calibre of a high end handmade like Leon Mege or Ocean pearlman they are amongst the best I've seen from CAD/CAM designers in your price range.

Share:

The Ultimate Guide to Men’s Wedding Bands: Metals, Fit & Finish

The Ultimate Guide to Men’s Wedding Bands: Metals, Fit & Finish - 06/27

Chipped Diamonds: Causes, Risks, and What You Should Do About It

Chipped Diamonds: Causes, Risks, and What You Should Do About It - 06/27

300x240.png)