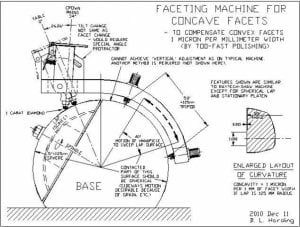

. Attached is a concept for a faceting machine which produces theoretically concave facets – to compensate for the convexity often found with flat laps when polishing too fast. Sergey Sivovolenko has mentioned the need for this twice now.

. Calculations (checked by enlarged layout) show that a 125mm (5 inch) radius lap surface will produce concavity 1 micron deep in a 1mm wide facet.

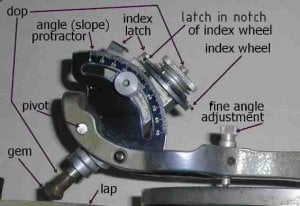

. The concept shown here shows components similar to my Raytech-Shaw faceter (similar to those used by most professional diamond cutters). The BIG difference, other than the spherical lap and platen surface, is that there is no means of ‘vertical’ adjustment for depth of stock removal; the ‘platen’ (tripod bearing surface) must be spherical and concentric with the lap sphere (not necessarily the same size, as shown here). This adjustment is another problem for another day.

. Note the that the change in dop tilt is not the same as the change in facet slope; this would require a non-standard protractor, graduated according to slope.

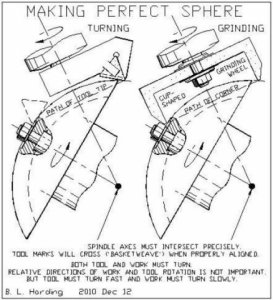

. A while back I told him about cylindrical laps used to fast-facet synthetic at least 35 years ago – so they could facet them faster with flatter-resulting facets. Too few of us are aware of what's going on in both fields - diamond and colored-stone cutting; we could learn more and progress faster if we were.

. Calculations (checked by enlarged layout) show that a 125mm (5 inch) radius lap surface will produce concavity 1 micron deep in a 1mm wide facet.

. The concept shown here shows components similar to my Raytech-Shaw faceter (similar to those used by most professional diamond cutters). The BIG difference, other than the spherical lap and platen surface, is that there is no means of ‘vertical’ adjustment for depth of stock removal; the ‘platen’ (tripod bearing surface) must be spherical and concentric with the lap sphere (not necessarily the same size, as shown here). This adjustment is another problem for another day.

. Note the that the change in dop tilt is not the same as the change in facet slope; this would require a non-standard protractor, graduated according to slope.

. A while back I told him about cylindrical laps used to fast-facet synthetic at least 35 years ago – so they could facet them faster with flatter-resulting facets. Too few of us are aware of what's going on in both fields - diamond and colored-stone cutting; we could learn more and progress faster if we were.

300x240.png)