- Joined

- Aug 15, 2000

- Messages

- 18,963

AGS Visual Proportion Analyser software is a little application that is free in a beta format.

You can download it by clicking the download button on the bottom of http://agslab.com/

It is a complex process. The manual that comes with it has the operating instructions on page 7 - copied here below to save you time:

How to Operate The Software

Copy the contents of the CD Rom to your desired location. Do not run the program from the CD. Open the folder entitled AGS_Visual_Performance_Analyzer. In order to process your own .stl or .srn files, place the files in the same directory of the VPA software. Double click the software AGS_Visual_Proportion_Analyzer.exe file and it will process the report files into a separate sub-folder called VPA_Images. Open that folder and enjoy looking at the images of diamonds cut to different degrees of precision.

Now on my computer the folders actually ended up back in the folder where the original .srn files came from. Not what I read in the instructions - but rather neat.

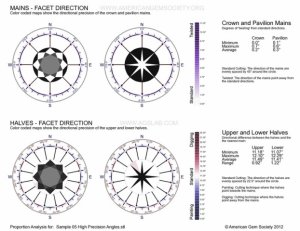

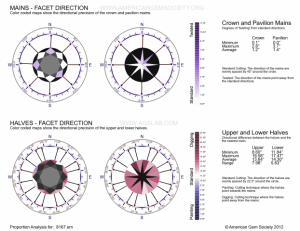

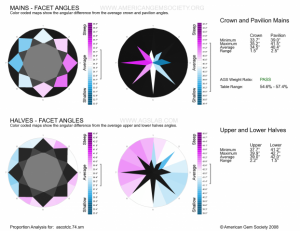

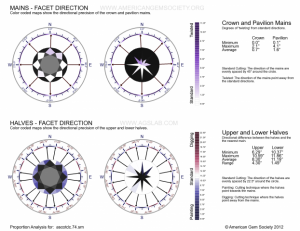

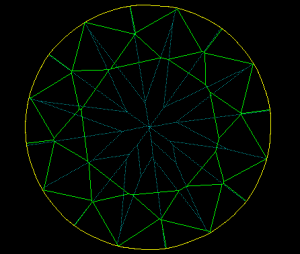

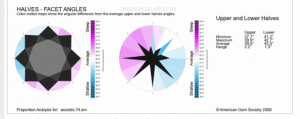

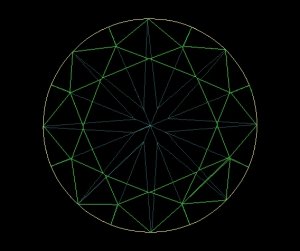

The charts produced show the angular and azimuth variation in simple images. It is an easy to follow system, and rather like GIA's recent announcement publishing the rules for Symmetry so that manufacturers know before sending a stone that they will achieve Excellent or at least Very Good - I guess this is also what AGS are doing.

Unfortunaltely it only works on Sarin srn files and .stl files.

On that matter there is an interesting article in Gems & Gemology by a team of GIA research scientists and cornel Uni folk that uses an ancient goniometer to measure the angles of stones to create calibration masters. They found that the scanner they compared had very large angular deviations from what they believe to be very accurate results from the Goniometer. They did not name the brand of scanner. The 5 stones they compared each had deviations of greater than 0.4 degrees. With that in mind one might need to be sure when using the AGS VPA software that its not GIGO.

I do not have time today for any more - but hopefully somone will post some of the display outputs.

You can download it by clicking the download button on the bottom of http://agslab.com/

It is a complex process. The manual that comes with it has the operating instructions on page 7 - copied here below to save you time:

How to Operate The Software

Copy the contents of the CD Rom to your desired location. Do not run the program from the CD. Open the folder entitled AGS_Visual_Performance_Analyzer. In order to process your own .stl or .srn files, place the files in the same directory of the VPA software. Double click the software AGS_Visual_Proportion_Analyzer.exe file and it will process the report files into a separate sub-folder called VPA_Images. Open that folder and enjoy looking at the images of diamonds cut to different degrees of precision.

Now on my computer the folders actually ended up back in the folder where the original .srn files came from. Not what I read in the instructions - but rather neat.

The charts produced show the angular and azimuth variation in simple images. It is an easy to follow system, and rather like GIA's recent announcement publishing the rules for Symmetry so that manufacturers know before sending a stone that they will achieve Excellent or at least Very Good - I guess this is also what AGS are doing.

Unfortunaltely it only works on Sarin srn files and .stl files.

On that matter there is an interesting article in Gems & Gemology by a team of GIA research scientists and cornel Uni folk that uses an ancient goniometer to measure the angles of stones to create calibration masters. They found that the scanner they compared had very large angular deviations from what they believe to be very accurate results from the Goniometer. They did not name the brand of scanner. The 5 stones they compared each had deviations of greater than 0.4 degrees. With that in mind one might need to be sure when using the AGS VPA software that its not GIGO.

I do not have time today for any more - but hopefully somone will post some of the display outputs.

300x240.png)