napatastic

Rough_Rock

- Joined

- Jan 23, 2014

- Messages

- 15

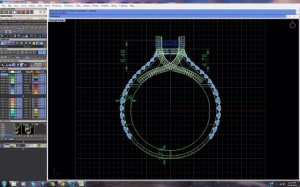

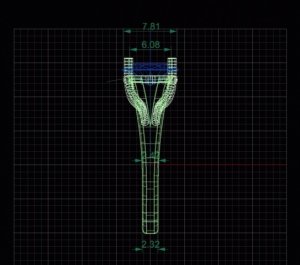

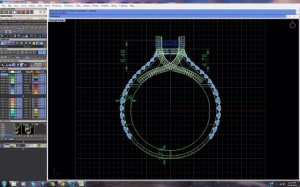

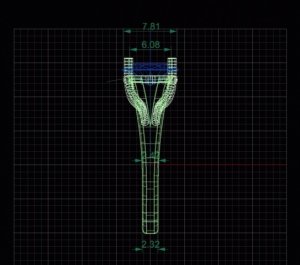

I am obsessing about the dimensions of the setting I am having custom made. (Mostly concerned about the DEPTH, not the width) It is meant to be a delicate, split shank with pave. But I feel like there is too much depth in the shank, on the CADs that I was sent. (Pictures showing dimensions attached below) I know that the various stages of pave work, and finishing that will happen between the initial casting and the finished product will shrink these dimensions a bit, but is that going to be by .02mm or 1.0mm?? I want the ring to be relatively low profile but not so delicate it breaks or warps. And most importantly, I want the ratio of visible pave to metal shank to be visually appealing. So,:

What are the "typical" dimensions of settings with pave? Specifically the shank portion.

What are the "typical" dimensions of settings with pave? Specifically the shank portion.

300x240.png)