- Joined

- Sep 3, 2000

- Messages

- 6,756

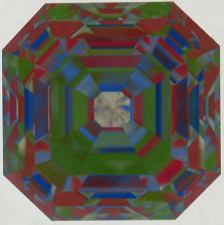

All the scanners which take side views of diamonds to measure them have an inherent and uncorrectable problem with getting exact width and length, and exact widths of the table. The only way around these issues is to combine the side views with top views. With a top view you can measure any set of points across the stone for width and length, and by highlighting the table with angled lighting, you can also get a very precise set of table measures. The top view allows for correct measures without regard to the alignment of the sides of the stone to one another, or the sides of the table to one another.

All side view scanners are forced to assume the sides are parallel and to some extent that the table orients with exactness to the sides of the stone. Many times, this is not the case at all.

Combining the top and side views in measuring diamonds electronically enhances the repeatability and accuracy of the measures. As the measures provided become more and more accurate, the ability to say more about the potential quality of the cut especially via a top and side scanner, is increased.

All side view scanners are forced to assume the sides are parallel and to some extent that the table orients with exactness to the sides of the stone. Many times, this is not the case at all.

Combining the top and side views in measuring diamonds electronically enhances the repeatability and accuracy of the measures. As the measures provided become more and more accurate, the ability to say more about the potential quality of the cut especially via a top and side scanner, is increased.

300x240.png)