- Joined

- Aug 15, 2000

- Messages

- 19,154

Wow, I guess women aren't allowed to work there! There's not a single woman in that video. (Unless the hands of the person in the packing department belong to a woman.)

Fascinating!

Is it so that the CVD process of lab diamonds is more straight forward than HPHT? In the CVD video the rough looked like a block whereas the HPHT looked more “natural”.

How much cheaper are lab diamonds to produce?

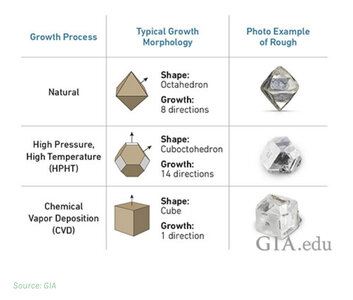

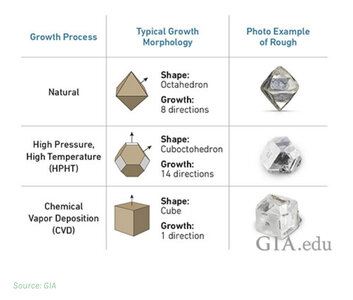

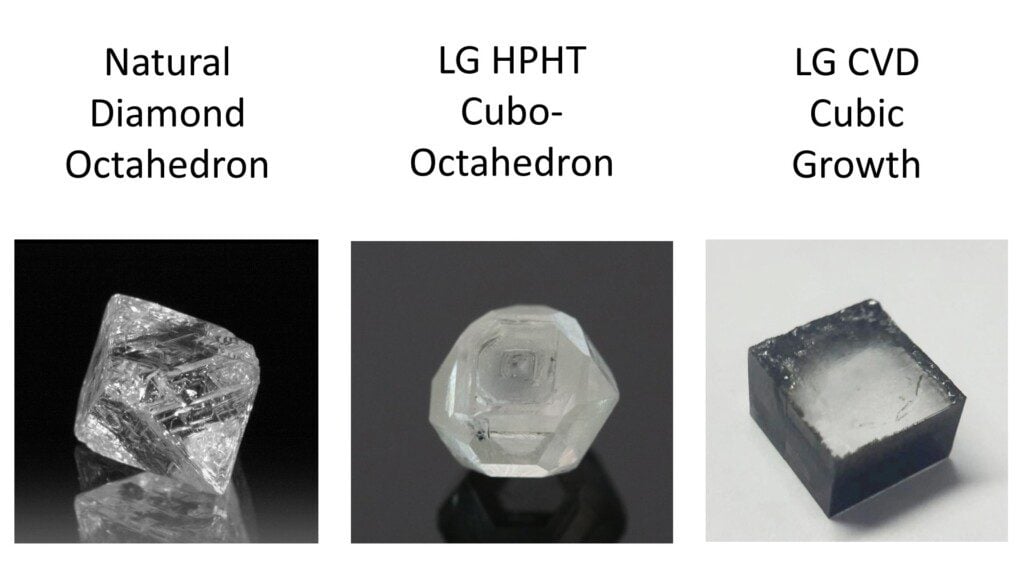

I found this picture online which I find interesting. I didn’t know that natural diamonds have 8 growth directions, whereas HPHT has 14 and CVD only one.

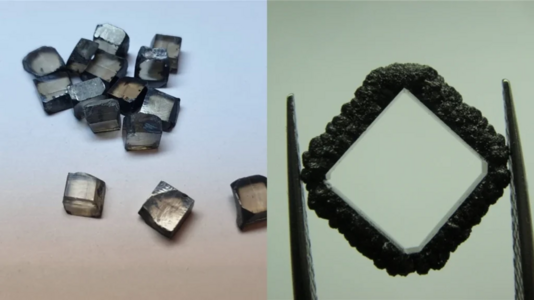

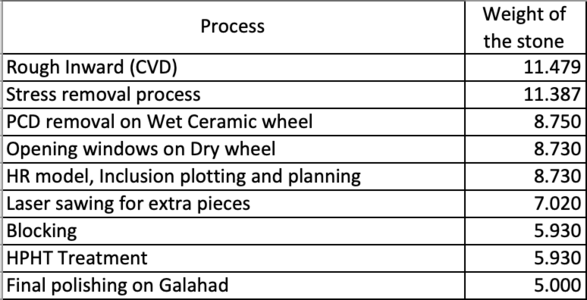

Many of them require hpht treatment to drive off the defects so its not all roses.Yes and as a result CVD tends to be cut shallower which makes better looking diamonds than natural or HPHT.

CVD can be grown to the depth required for say a 1ct order

Fascinating!

Is it so that the CVD process of lab diamonds is more straight forward than HPHT? In the CVD video the rough looked like a block whereas the HPHT looked more “natural”.

How much cheaper are lab diamonds to produce?

I found this picture online which I find interesting. I didn’t know that natural diamonds have 8 growth directions, whereas HPHT has 14 and CVD only one.

Many of them require hpht treatment to drive off the defects so its not all roses.

I have visited this factory in Surat a few times. The owners are highly ethical and very clever.

Very little is left to chance.

Enjoy: