How Are Diamonds Made? Natural vs Lab-Created Explained

Two Paths, One Diamond Not all diamonds come from the same place — but they all start the same way. Pure carbon, crystalized under immense pressure and heat. Whether it…

AGS has given us cut-grading standards for Princess cuts. Designs having pavilions with 2 chevrons came first and, just recently, those with 3 and 4 chevrons. I prefer designs with minimum facets because they give stronger ‘bang-bang’ on-off reflections/contrast that attract the eye; they also take less time to cut and offer less chance of cutting errors…

Their charts show the grades according to combinations of the slopes of the main facets. We know that this is a good guide – as with round brilliants – but that the ‘secondary’ facets may contribute significantly to the appearance of the stone.

I saw a broker looking at FireScope or IdealScope image simulations by software to see what these cuts would look like. However, the image he saw will not be what he is getting if the secondary facets are not cut the same way as they are represented in the computer model that is making the image.

There are many ways to cut the facets of a Princess cut. These variations will affect the actual FireScope and IdealScope images and may affect the beauty of the stone in relation to the cut grades.

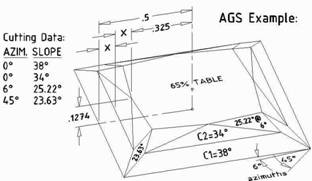

Fig.2 shows the Princess crown with beveled corners. This is pretty straightforward. The only data listed by AGS to find the cut-grade in their charts are the slopes of the two main facets, C1 and C2, and table size. These do not completely define the crown.

AGS assumes that the azimuth of the ‘star’ facets is 6? *; this defines the table. They also assume that main facets C1 & C2 are of equal width at the mid-side. With these assumptions the crown is completely defined; the height, and the slopes of the corner and star facets can be determined from these data.

If a cutter uses different assumptions the crown will have a different height and the slopes of the corner and star facets will be different. This will produce a real image which is different from that generated by the computer-model and may not comply with the AGS grade.

|

|

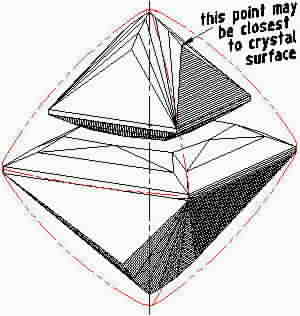

| Fig.1 The shape of the Princess retains much weight of a well-formed octahedral crystal. |

Fig.2 The crown initially cited by AGS. |

* GemCAD data listed by AGS in one publication cite the index as 1/64 circle, = azimuth of 5.625? but the other data in the same chart agree with 6? azimuth (= index of 1/60 circle).

The Princess Pavilion

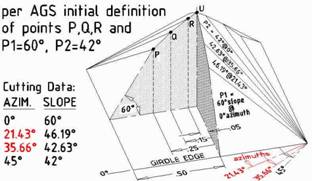

Fig.3 shows a princess pavilion with 2 ‘chevrons’. To identify the cutting grade, AGS lists only the slopes of the side main P1 and the corner facet P2. This does not completely define the pavilion but does define its height U.

|

|

| Fig.3 Note odd chevron azimuths which result from specifying too many other things. |

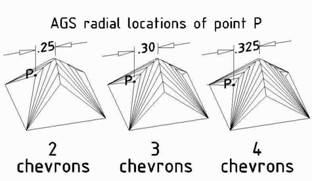

Fig.4 Similar appearance of 2- ,3-, and 4-chevron designs, but note location of point P. |

AGS assumes that points P,Q,R are located at distances .05,.15,.25 from the center of the gem (girdle width 1.0). This defines the heights of points P and R but the height of Q is still arbitrary. AGS chose a rule to define this point (now changed). Knowing the height of Q also, it becomes possible to define the azimuths and slopes of the two chevrons

This approach resulted in azimuths which were different for most combinations of slopes P1 & P2. This is impractical in a diamond-cutting shop because it would require a different click wheel for each combination.

New cutting data are in progress where the azimuths are specified to be the same for many cuts and the corner slope P2 is specified; slope P1 of the side main depends on these choices.

This is not a problem; choose the corner slope P2 you want and see what the side main slope P1 will be. The pixels on the AGS grading chart are large and you can find this combination within one of them.

In their new modeling, AGS has chosen the azimuths to be whole degrees. This is not necessary; many common indexes (using toothed wheels) are not whole degrees. It is okay for production cutters of one material, who can have special wheels made, but not for colored-stone cutters, who use wheels full of evenly-spaced teeth – such as 64, 72, 96, and 120 teeth (increments of 5.625?, 5?, 3.75?, 3? respectively).

Fig.4 shows Princess pavilions with 2, 3 and 4-chevrons. 3- and 4-chevron designs have the same problems as discussed above for the 2-chevron design and are receiving similar corrections.

A broker told me he prefers the 3- and 4- chevron designs because they have steeper side main P1 and thus more weight from the crystal. This may be true if the gems are cut as AGS defined them – note that they specified P1 as steeper and the radius to point P greater than in the 2-chevron design. These differences are not necessary; the 2-chevron design could have the same side slope at the same radius as the others. There are so many variables that one cannot make such generalizations.

Recall that the cut-grading charts provided by AGS are a grid of BOTH crown and pavilion slope combinations. The probability of the grades and virtual images matching what you actually get is therefore doubly-questionable – you must find out if the software models and the charts match the actual cutting configuration.

B. L. Harding 2005 Aug 05