Some time ago, I reported you about our experiences while cutting the first princess-cuts, in order to obtain the new AGS-0-cut-grade.

Last week, we received a first batch of six stones back from AGS. Let me tell you how we experience the grading of AGS.

1. The grading system

Where the current cut-grade consists of the following three factors, proportions, polish and symmetry, the new grade will have three different factors:

- Light performance

- Proportion factors

- Finish

1.1. Proportion factors

This factor is on the one hand a very important factor, while on the other hand, it is relatively easy to achieve an Ideal grade. In this factor, certain detrimental effects are observed:

- The girdle thickness is checked in order to make sure that the diamond has neither a too thin nor a too thick girdle.

- The culet size is checked.

- A spread-factor is observed, in order to make sure that a diamond has a surface, which is in line with its weight.

- Durability issues are checked, like a too thin girdle or a too low crown angle.

- Finally, tilt is checked, in order to make sure that the girdle does not reflect under the table, after minimally tilting the diamond.

For a cutter, aiming for AGS-0, obtaining Ideal on this factor is straightforward and easy. For a consumer however, this is a very important factor, since it addresses very important problems like durability and spread.

1.2. Finish

Finish consists of two factors that we already know, polish and symmetry. This grading basically is the same as in the current AGS-system for rounds.

At the end of last year, one could deduct from some AGS-presentations, that the grading for Polish and Symmetry would be loosened to the extent that the current Excellent-grade would be included in an Ideal-grade. Apparently, this idea was abandoned, and there still is a clear distinction between the Ideal and the Excellent grade.

1.3. Light performance

Light performance consists of brightness (or brilliance), fire, scintillation and contrast. AGS has developed a complete software-system, based upon its studies, and they use this software to judge light performance.

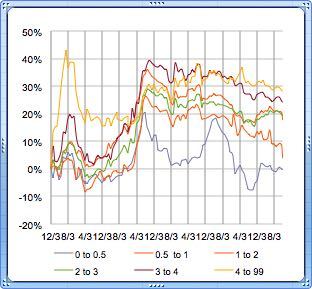

In order to help cutters, AGS has distributed ‘cutting guidelines’, which gives combinations of proportions, that should yield candidates for AGS-0, and for all the other AGS-scores. However, it is very important to understand that ‘cutting guidelines’ are not ‘grading guidelines’.

In grading, the first step is to take a 3D-scan of the diamond. After the accuracy of this scan is checked, it is introduced into the AGS-software. This software performs a series of ray-tracing, and finally returns scores according to the AGS ASET-system. These scores are compared to certain values, and if a diamond scores in the Ideal-range on all these scores, it will be graded Ideal on Light Performance.

Light Performance-grading will make the big difference with the current AGS-system. While, in theory, a cutter has many more possible combinations to cut an AGS-0, each combination needs such total precision that it is very difficult to obtain this.

Our experience with the grading system

We have sent a first batch of 6 stones to AGS, ranging from 0.78 Ct up to 1.34 Ct. All 6 were cut within the ‘cutting guidelines’ for AGS-0. While cutting however, we aimed at very small AGS-0-areas in the cutting-guideline-charts, since this would ultimately give us the most information on how the system actually works.

2.1. Proportion factors

As expected, this factor does not represent any difficulty. All 6 are Ideal. I do wonder at what point a diamond will start to be downgraded on Proportion Factors, since it is a very important factor for consumers. Where a Very Good on Light Performance still is a very beautiful stone, it might well be that a Very Good on Proportion Factors should not be considered as a decent purchase.

2.2. Finish

Symmetry in a fancy shape is much more difficult to obtain than in a round. In rounds, one has the advantage of the symmetrical round shape, but also the cutting equipment allows to hold a round stone much better than a fancy shape.

A similar difficulty can be observed in Polish. When cutting a fancy shape, one encounters more often a facet that is difficult to smooth. Because of this, Ideal Polish in a fancy shape is more difficult to obtain than in a round.

Of our 6 stones, 5 scored Ideal on Polish (1 Excellent) and 3 scored Ideal on Symmetry (3 Excellents). What is weird, is that while 2 scored Excellent on Symmetry, they still received an Ideal score on Finish.

Looking at the stones, the reasons why some did not get Ideal are pretty straightforward, and rather easy to repair. After some experience, a cutter should be able to get a very high performance of Ideal-scores on Finish.

2.3. Light performance

Obtaining Ideal Light Performance will be the cutters’ nightmare. We encountered the following problems.

When choosing for a specific combo of proportions, we used the cutting-guidelines and Diamcalc, in order to check the appearance of the chosen combo. It was weird to see that when we compared the estimated final weight in Diamcalc, with that for the same combo in Sarin, there was a discrepancy, which often was considerable.

Cutting according to the chosen proportions was not really a difficulty, although with the guidelines working with 1°-steps, one is not sure in which direction one can allow deviations.

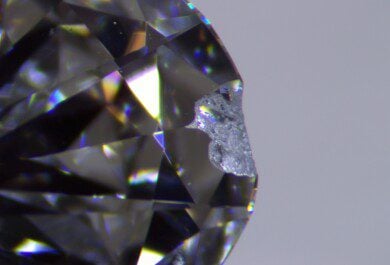

The true frustration starts when one wants to check the measurements of the finished stone. Both Sarin and OGI were unable to correctly measure the crown area of a princess. Especially, the measurement of the C2-angle and the Table-size were completely off. Apparently, the angle of the C2-angle is so low, and the facet relatively small, so that in the shadow-image, both Sarin and OGI often miss this facet, thus measuring a much bigger table size than actually is the case, and almost no C2-facets.

We understand that AGS also works with Helium-machines to measure, and we hope that they are more accurate in this area.

Of our 6 stones, 2 scored Ideal on Light Performance, the other 4 are Excellents. Knowing that we were aiming at very small 0-areas in the cutting guidelines, we are quite happy with these results.

Testing the performance of the stones

Before and after we sent the stones to AGS, we have tested their light performance with a number of professional and amateur observers.

The professionals all agreed that all 6 are princess-cuts, like they had never seen before. Compared to the traditional princess-cuts on the market, these offer a play of brilliance, fire and scintillation that is much closer to that of a round, than one is used to in princess-cuts.

As for both professionals and amateurs, it is interesting to note that some preferred stones that graded Excellent on Light Performance above stones that graded Ideal.

Conclusion

Checking the stones after their grading, we have decided to repair 4 stones on either Polish or Symmetry. These repairs are relatively easy, and the errors are avoidable in the following stones.

At the same time, we have decided not to repair stones with Excellent Light Performance, since they are extremely beautiful as they are, and the direction in which to work in order to obtain Ideal from here, is either unclear, or brings about a high loss of weight.

This means that we will be selling stones with AGS-1 (1 on Light Performance only) from now on, and that, within a few weeks, we will also have stones with full AGS-0-reports.

Discuss…