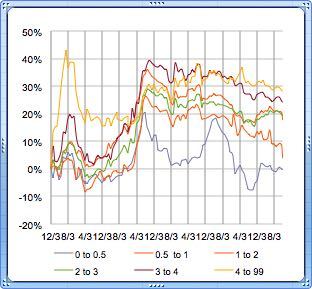

Natural Diamond Prices – May 2025

PriceScope provides detailed monthly insights into the natural diamond market, serving consumers, traders, and industry professionals. This report explores April’s diamond price fluctuations, driven by key market factors, and offers…