How Are Diamonds Made? Natural vs Lab-Created Explained

Two Paths, One Diamond Not all diamonds come from the same place — but they all start the same way. Pure carbon, crystalized under immense pressure and heat. Whether it…

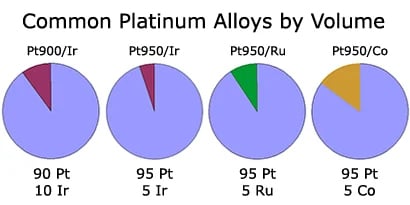

Many alloys exist and new ones are constantly being developed. Here is an overview of some of the most common ones encountered in the crafting of jewelry, with a focus on platinum vs white gold.

Before going on: Check out the PriceScope Diamond Buying Guide

Wondering which of the many diamond colors is best for you? Our elite list of vetted vendors like Whiteflash and James Allen are experts at listening and helping you determine which combo of the 4Cs is perfect for you - and nicely in budget. Contact Us and get help today.

Fine jewelry settings are created from precious metals. This page provides information about gold, white gold, rhodium plating, and nickel allergies, as well as fine distinctions between the more common platinum alloys. We will also cover platinum vs white gold and much more.

When considering white gold vs platinum, remember that about 15% of people are impacted by metal allergy, a condition where the body perceives certain types of metals as toxins. Nickel, used in some white gold and copper alloys, causes the most trouble for those with metal allergies. The safest, most hypoallergenic jewelry for those who may have sensitive skin or known allergies is platinum.

Gold is popular because it can be worked into almost any shape. Yellow gold jewelry of 18K and above does not tarnish and rarely causes problems for people with skin irritations. When considering white gold vs platinum, the wider availability and price point of gold compared to platinum alloys appeals to many people.

1. 18K Yellow Gold

2. 18K White Gold (Nickel White Gold)

18K Palladium White Gold3

Understanding Platinum

Platinum is a precious metal renowned for its brilliance, durability, and naturally white color. Unlike white gold, platinum does not require alloying with other metals to achieve its white hue. This rarity and purity contribute to its allure and prestige in fine jewelry. Platinum’s innate properties make it an appealing choice for those seeking a metal that maintains its pristine appearance over time.

Platinum is also hypoallergenic, making it suitable for people with sensitive skin or allergies to metals like nickel, commonly found in white gold.

White gold, in contrast, is an alloy comprising gold and one or more white metals like palladium, nickel, zinc, copper, or silver. This combination transforms the naturally yellow gold into a white metal, making it a versatile and cost-effective option for jewelry enthusiasts. However, white gold requires rhodium plating to enhance its whiteness and brilliance, and this plating may need periodic maintenance over time to maintain its bright white finish.

There are 4 platinum alloys commonly used in the USA. From softest to hardest:

A medium-hard alloy which is malleable and well-suited for bench work, 950 PLAT/IR is good for both casting and handmade pieces. It is a top choice for soft or fragile gem setting. The greater softness requires a longer polishing process. It is also less scratch and bend resistant than harder alloys, but holds a stone better if an impact occurs, like a shock absorber. Over time it is very resistant to signs of wear. When visually comparing platinum vs white gold, 950 PLAT/IR is more gray than new rhodium plating.

A great combination of hardness and malleability, 900 PLAT/IR is easy to polish and has good white color. It is excellent for both casting and handmade work. Less pressure is required to set gemstones than with harder alloys. It is resistant to scratching and bending and over time, is very resistant to signs of wear. When visually comparing platinum vs white gold, 900 PLAT/IR is slightly more gray than new rhodium plating.

950 PLAT/RU is extremely hard. It has the highest melting temperature of all platinum alloys. Somewhat darker gray in color than platinum-iridium, it is less malleable, more challenging to solder and weld, and hard to burnish. Bench workers find it tough on burs, files and drills. Some setters recommend it for diamonds only, since more pressure must be imposed on gemstones during the setting process. It is extremely scratch and bend-resistant and extremely resistant to signs of wear over time. When visually comparing platinum and white gold, 950 PLAT/RU is slightly more gray than new rhodium plating.

950 PLAT/CO has the lowest flow point of common platinum alloys, making it good for even, dense castings, but not for work by hand. This alloy tarnishes when heated, so it needs flux and pickling after soldering just like gold – unlike other platinum alloys. While it takes a fast polish, it finishes darker gray than iridium. It requires moderate pressure on gemstones during the setting process. Bench workers find it more “gold-like” and easy on the tools. It holds up to wear quite well over time. Cobalt is a ferrous metal not from the platinum group, so its scraps must be kept separate from other platinum scraps. When visually comparing platinum and white gold, 950 PLAT/CO is more gray than new rhodium plating and more gray than other platinum alloys.

950 and 900 PLAT/IR are the whitest and softest of the common alloys, excellent for production and setting. They solder and weld more easily than other platinum alloys. 900 PLAT/IR is a popular and traditional standard in the USA. The global platinum standard is 95% by weight, so producers with a global clientele frequently use 950 PLAT/IR. In any comparison of platinum vs white gold, the alloy will be slightly more gray than new rhodium plating.

Wear luxury with platinum and white gold jewelry from Whiteflash and James Allen. Discover unique design and timeless beauty for your most treasured moments.

White gold requires alloying with other metals to achieve its white appearance. Over time, the rhodium plating on white gold can wear off, revealing a slight yellowish tint, necessitating regular maintenance.

In contrast, platinum’s natural white hue remains unaffected by time or wear. Its enduring color makes it an ideal choice for those seeking a metal with long-lasting beauty and elegance.

When people hear 950 PLAT described as 95% platinum, they assume that means 95% by volume, it doesn’t. The percentage is by weight. Platinum is the heaviest of these metals. Therefore, it requires far more than 5% by volume of a lighter metal to match platinum by 5% in weight.

| Metal | Atomic Weight |

| Platinum | 195.078 |

| Iridium | 192.217 |

| Ruthenium | 101.070 |

| Cobalt | 058.933 |

18K gold is the most recognized global standard and will be marked ’18K’ in the USA and ‘750’ in Europe.

Platinum commands a higher price compared to white gold due to its rarity, density, and purity. The increased cost reflects the greater quantity of platinum required to craft a piece of jewelry.

White gold offers a more budget-friendly alternative upfront, but its long-term maintenance costs, including periodic rhodium replating, should be considered when evaluating its overall value.

Platinum’s density and weight contribute to its exceptional durability, making it less prone to scratching or wearing down over time. When platinum is scratched, no material is lost, as the metal is merely displaced, preserving its volume.

White gold, while durable, may require more frequent maintenance to uphold its appearance, especially if it undergoes rhodium plating regularly.

Comparison Chart

| Alloy | Hardness | Durability |

| 18k Gold | 125 HV | 29,000 PSI |

| 950 PLAT/IR | 80 HV | 40,000 PSI |

| 900 PLAT/IR | 110 HV | 55,000 PSI |

| 950 PLAT/RU | 130 HV | 66,000 PSI |

| 950 PLAT/CO | 135 HV | 64,000 PSI |

Gold is harder than some of the platinum alloys and will resist scratches better. Platinum is almost twice as durable as gold, is more ductile and has much greater longevity. For the body of a piece the differences are not critical. For the prongs, there are implications: for instance, white gold prongs will break. Yellow gold prongs will bend more, as will platinum, but platinum prongs are more durable over time. In any question of white gold vs platinum prongs platinum is recommended.

Platinum enjoys enduring popularity, prized for its rarity, longevity, and timeless elegance. It remains a preferred choice for engagement rings and wedding bands, reflecting a commitment to quality and sophistication.

White gold, though also popular, may see its appeal fluctuate with trends and fashion preferences. Its affordability and versatility continue to attract a wide audience.

When selecting between white gold and platinum, several key considerations can guide your decision-making process:

Metal Sensitivities Platinum’s hypoallergenic properties make it an excellent choice for those with allergies to metals like nickel. If you have metal sensitivities, opting for platinum can ensure greater comfort.

Budget White gold is a more affordable option for those looking to balance cost and style. However, factoring in the long-term maintenance costs of rhodium replating can give you a better idea of its overall value.

Style Coordination If you’re choosing a metal for both an engagement ring and a wedding band, consider the aesthetic harmony of matching metals. Whether you opt for the timeless elegance of platinum or the affordability of white gold, ensure that your chosen metals complement your overall style.

Embark on a journey of sophistication and splendor with PriceScope vendors like Whiteflash, Blue Nile and James Allen. Explore exquisite craftsmanship and enduring elegance, perfect for capturing life's most precious moments

When considering platinum vs white gold, the alloys above are the most common by far, but many other alloys exist.

Stuller’s X1 (extreme white) White gold is formulated to achieve a very good white color, without the need for rhodium plating. When considering white gold vs platinum, many people prefer an option like this, which is naturally white. It has a high nickel content, so it is not hypoallergenic.

White gold alloys using chromium and iron instead of nickel have been developed to address nickel allergies.

Colored gold alloys range from 8K to 22K in gold content and can be produced in color shades such as rose and red (greater copper content), green (more silver) and even purple (gold-aluminum). When considering white gold vs platinum, note that these choices are only available in gold alloys.

950 Palladium is similar to platinum alloys; 95% palladium alloyed with 5% ruthenium by weight. Like platinum alloys, it only requires occasional re-polish. However, it is not as white as more common platinum/iridium alloys and is priced similarly, and not many people work with it. When visually comparing white gold vs platinum vs palladium, newly rhodium-plated white gold is always more white.

Plat/S+ is another 950 platinum alloy offered by Hoover & Strong (the remaining ingredients are proprietary). Harder than other traditional platinum alloys, it was developed by the late Steven Kretchmer, who introduced tension-set rings in the USA, under the name SK Platinum.

950 PlatOro is 95% platinum and 5% gold by weight. Also from Hoover & Strong, it has high flow characteristics which keep porosity to a minimum. It is ductile, with similar hardness to Pt950/Ru.

New alloys are constantly being developed. As with precious stones, the variety of offerings and options available to the consumer in precious metals and alloys reflects the wide variety of taste among enthusiasts. In any decisions of white gold vs platinum vs palladium vs any other metal, the choice becomes personal.

In the realm of fine jewelry, the choice between white gold and platinum ultimately boils down to personal preferences, budget considerations, and lifestyle factors. Platinum offers unparalleled durability, hypoallergenic properties, and a naturally white hue, making it a great option for those seeking long-term wear and elegance. White gold, while more affordable, provides versatility and a similar aesthetic at a lower upfront cost but requires periodic maintenance.

By weighing the distinctive characteristics and shopping considerations outlined in this guide, you can confidently select the metal that best represents your love, style, and commitment for years to come.

Get fast answers to any question: Ask our community of unbiased independent helpers.

Ready to find your diamond?

Our thanks to John Pollard, educational specialist, and the photography team at Whiteflash for providing much of the content above.

Retail Diamond Prices Chart Updated Monthly.

Two Paths, One Diamond Not all diamonds come from the same place — but they all start the same way. Pure carbon, crystalized under immense pressure and heat. Whether it…

A Wedding Ring as Unique as Your Love Finding the right wedding ring isn’t just about diamonds or gold – it’s about finding the one that feels right. With hundreds…

So, you’re thinking about lab-grown diamonds? Smart move. They’re just as sparkly as the natural kind but usually cost less. But where do you actually go to buy them? It…

Want to stay updated on the most recent blogs, forum posts, and educational articles? Sign up for Bling News, PriceScope’s weekly newsletter.