Precious Metal Overview

Fine jewelry settings are created from precious metals. This page provides information about gold, white gold, rhodium plating, and nickel allergies, as well as fine distinctions between the more common platinum alloys. We will also cover platinum vs white gold and much more.

Metal Allergies

When considering white gold vs platinum, remember that about 15% of people are impacted by metal allergy, a condition where the body perceives certain types of metals as toxins. Nickel, used in some white gold and copper alloys, causes the most trouble for those with metal allergies. The safest, most hypoallergenic jewelry for those who may have sensitive skin or known allergies is platinum.

Gold Alloys

Gold is popular because it can be worked into almost any shape. Yellow gold jewelry of 18K and above does not tarnish and rarely causes problems for people with skin irritations. When considering white gold vs platinum, the wider availability and price point of gold compared to platinum alloys appeals to many people.

Common Fine Gold Alloys

- 18K yellow gold

- 18K white gold, rhodium plated

- 18K palladium white gold, not plated

1. 18K Yellow Gold

- 75% Gold, alloyed with Copper, Silver, Zinc and/or Cobalt

- Does not require plating

- + Very workable

- + Rarely causes skin irritation

- – Will wear down, but over a long period of time with heavy wear

2. 18K White Gold (Nickel White Gold)

- 75% Gold, alloyed with Copper, Nickel, Zinc and/or Palladium

- Requires rhodium plating and re-plating over time, depending on wear

- + Less workable, less ductile

- – Causes skin irritation for people with nickel allergies

- – Will wear down over a long period of time

18K Palladium White Gold3

- 75% Gold, 25% Palladium

- Requires rhodium plating and re-plating over time, depending on wear

- + Very workable

- + Rarely, if ever, causes skin irritation

- – Will wear down over a long period of time

- – More expensive than 18K nickel WG

Understanding Platinum

Platinum is a precious metal renowned for its brilliance, durability, and naturally white color. Unlike white gold, platinum does not require alloying with other metals to achieve its white hue. This rarity and purity contribute to its allure and prestige in fine jewelry. Platinum’s innate properties make it an appealing choice for those seeking a metal that maintains its pristine appearance over time.

Platinum is also hypoallergenic, making it suitable for people with sensitive skin or allergies to metals like nickel, commonly found in white gold.

Exploring White Gold

White gold, in contrast, is an alloy comprising gold and one or more white metals like palladium, nickel, zinc, copper, or silver. This combination transforms the naturally yellow gold into a white metal, making it a versatile and cost-effective option for jewelry enthusiasts. However, white gold requires rhodium plating to enhance its whiteness and brilliance, and this plating may need periodic maintenance over time to maintain its bright white finish.

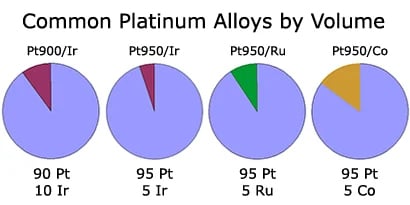

Common Platinum Alloys

- Platinum-iridium

- Platinum-ruthenium

- Platinum-cobalt

There are 4 platinum alloys commonly used in the USA. From softest to hardest:

- 950 PLAT/IR = 950 parts platinum, 50 parts Iridium

- 900 PLAT/IR = 900 parts platinum, 100 parts Iridium

- 950 PLAT/RU = 950 parts platinum, 50 parts Ruthenium

- 950 PLAT/CO = 950 parts platinum, 50 parts Cobalt

950 Platinum alloyed with Iridium

A medium-hard alloy which is malleable and well-suited for bench work, 950 PLAT/IR is good for both casting and handmade pieces. It is a top choice for soft or fragile gem setting. The greater softness requires a longer polishing process. It is also less scratch and bend resistant than harder alloys, but holds a stone better if an impact occurs, like a shock absorber. Over time it is very resistant to signs of wear. When visually comparing platinum vs white gold, 950 PLAT/IR is more gray than new rhodium plating.

900 Platinum alloyed with Iridium

A great combination of hardness and malleability, 900 PLAT/IR is easy to polish and has good white color. It is excellent for both casting and handmade work. Less pressure is required to set gemstones than with harder alloys. It is resistant to scratching and bending and over time, is very resistant to signs of wear. When visually comparing platinum vs white gold, 900 PLAT/IR is slightly more gray than new rhodium plating.

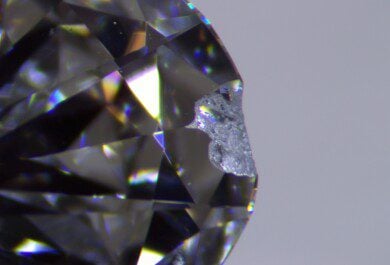

950 Platinum alloyed with Ruthenium

950 PLAT/RU is extremely hard. It has the highest melting temperature of all platinum alloys. Somewhat darker gray in color than platinum-iridium, it is less malleable, more challenging to solder and weld, and hard to burnish. Bench workers find it tough on burs, files and drills. Some setters recommend it for diamonds only, since more pressure must be imposed on gemstones during the setting process. It is extremely scratch and bend-resistant and extremely resistant to signs of wear over time. When visually comparing platinum and white gold, 950 PLAT/RU is slightly more gray than new rhodium plating.

950 Platinum alloyed with Cobalt

950 PLAT/CO has the lowest flow point of common platinum alloys, making it good for even, dense castings, but not for work by hand. This alloy tarnishes when heated, so it needs flux and pickling after soldering just like gold – unlike other platinum alloys. While it takes a fast polish, it finishes darker gray than iridium. It requires moderate pressure on gemstones during the setting process. Bench workers find it more “gold-like” and easy on the tools. It holds up to wear quite well over time. Cobalt is a ferrous metal not from the platinum group, so its scraps must be kept separate from other platinum scraps. When visually comparing platinum and white gold, 950 PLAT/CO is more gray than new rhodium plating and more gray than other platinum alloys.

Summary

950 and 900 PLAT/IR are the whitest and softest of the common alloys, excellent for production and setting. They solder and weld more easily than other platinum alloys. 900 PLAT/IR is a popular and traditional standard in the USA. The global platinum standard is 95% by weight, so producers with a global clientele frequently use 950 PLAT/IR. In any comparison of platinum vs white gold, the alloy will be slightly more gray than new rhodium plating.