You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

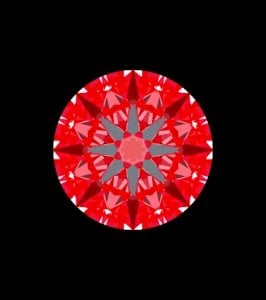

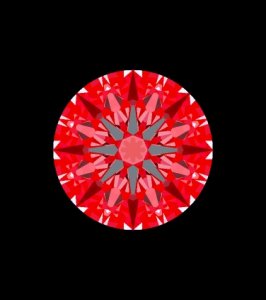

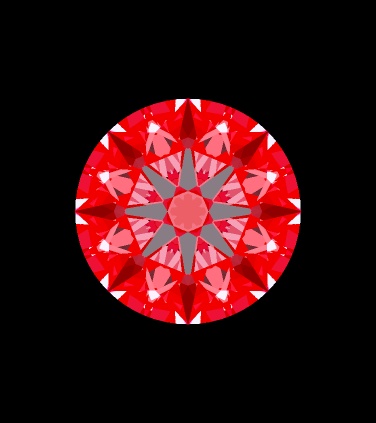

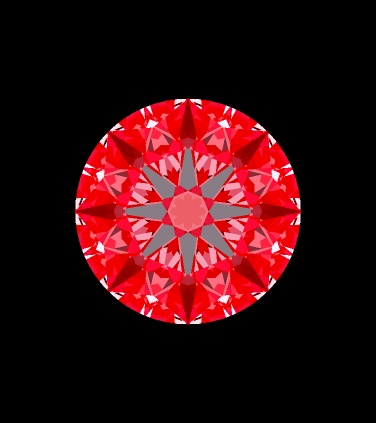

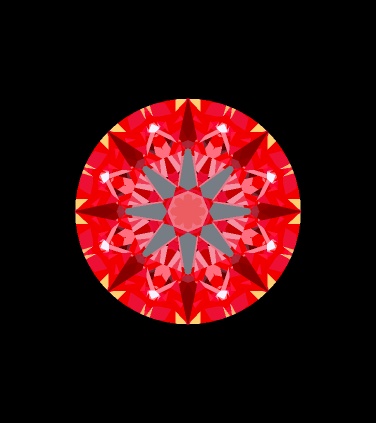

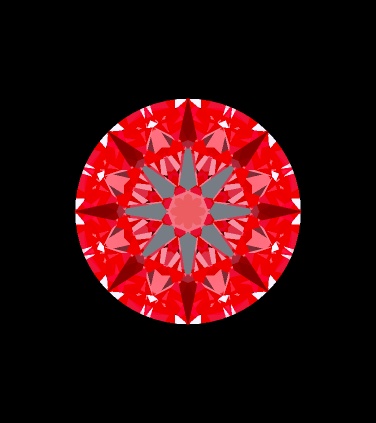

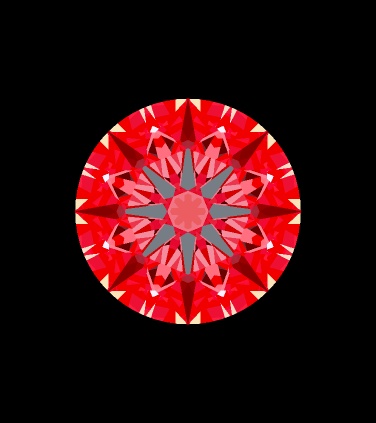

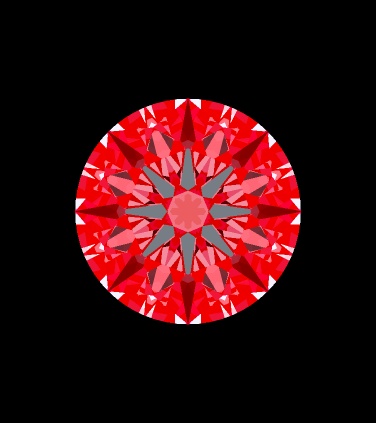

Long stars

- Thread starter strmrdr

- Start date

- Status

- Not open for further replies. Please create a new topic or request for this thread to be opened.

- Joined

- Aug 15, 2000

- Messages

- 18,484

1. I would be happy with any one of them Storm.

2. try this - increase the carat weight to 100ct or 1,000 ct and see how little difference the upper and lower girdles make to weight and therefore cutters yeild.

3. Others have suggested that incorrect minor facets are cut for getting better yeilds and disguising weight. This is simply wrong. I have worked with many manufacturers who are now aware that lower girdles neeed to be adjusted for different table sizes to keep a nice star width. They all want to get the best looking diamonds they can when there is no cost disadvantage.

But of more interest is to play with slightly shallow or slightly deep diamonds - not ones near a sweet spot. Then the minor facets can really make a difference, which is why I always have said that in the sweet spots of HCA the minor facets do not make much difference.

2. try this - increase the carat weight to 100ct or 1,000 ct and see how little difference the upper and lower girdles make to weight and therefore cutters yeild.

3. Others have suggested that incorrect minor facets are cut for getting better yeilds and disguising weight. This is simply wrong. I have worked with many manufacturers who are now aware that lower girdles neeed to be adjusted for different table sizes to keep a nice star width. They all want to get the best looking diamonds they can when there is no cost disadvantage.

But of more interest is to play with slightly shallow or slightly deep diamonds - not ones near a sweet spot. Then the minor facets can really make a difference, which is why I always have said that in the sweet spots of HCA the minor facets do not make much difference.

strmrdr

Super_Ideal_Rock

- Joined

- Nov 1, 2003

- Messages

- 23,295

Yea Garry the difference that are showing up are personality tweaks nothing more.

I ran a much wider range thru various combos and like you said until you go to the extremes it was pretty much personality tweaks because the differences weren''t big enough to be called performance differences.

I ran a much wider range thru various combos and like you said until you go to the extremes it was pretty much personality tweaks because the differences weren''t big enough to be called performance differences.

JohnQuixote

Ideal_Rock

- Joined

- Sep 9, 2004

- Messages

- 5,212

Date: 8/8/2005 5:36:51 PM

Author: Garry H (Cut Nut)

1. I would be happy with any one of them Storm.

2. try this - increase the carat weight to 100ct or 1,000 ct and see how little difference the upper and lower girdles make to weight and therefore cutters yeild.

3. Others have suggested that incorrect minor facets are cut for getting better yeilds and disguising weight. This is simply wrong. I have worked with many manufacturers who are now aware that lower girdles neeed to be adjusted for different table sizes to keep a nice star width. They all want to get the best looking diamonds they can when there is no cost disadvantage.

But of more interest is to play with slightly shallow or slightly deep diamonds - not ones near a sweet spot. Then the minor facets can really make a difference, which is why I always have said that in the sweet spots of HCA the minor facets do not make much difference.

Strm asked me to comment in this thread.

I'd be happy with these as well...Of course I'd rather see actual diamonds than models.

Diamonds are not stamped out, and recovery for any manufacturer is prime importance. It's a matter of cost. The weight recovery for the rough will dictate whether they make nice stones or just commercially viable hepgush. Smaller goods produces en masse will show more variance. Most fine make diamonds are already slated for less weight recovery.

Incidentally, my understanding about saving weight with longer LGFs was derived from the fundamental that they are closer in angle to the pavilion mains when longer, thus less must be polished away. However, running your 100ct experiment in DC it calculates more weight saved with short LGFs (?).

Any insight Garry? I know pavilion mains are put on first when it's blocked in 8. Is this DC not emulating rough-to-polished planning/design or am I backwards here?

As for minors making a difference near sweet spots. Some of us who are into precisely patterned diamonds note differences in different lighting conditions that correlate to the minors. This relies on combos of majors, minors and the level of patterning.

mkb

Rough_Rock

- Joined

- Jul 1, 2005

- Messages

- 47

John,

as Gary said in reality there is very little to gain in weight with the length of the bottom halves (lower girdles). If weight is that critical in a particular stone (eg. Risking a 0.99 instead of a 1.00 ct) the cutter would be better off to cut the halves say 9.5 degrees away from the pavilion (instead of 11.25), H&A would then be out of the question, but would probably still get a better price without certification.

Although stones are blocked on the pavilions, in these ‘super cuts’, while finishing halves are cut first.

I’ll ad a few pages out of my training manual (not aimed at H&A), here the halves are 80%, as is usually used in smaller goods (VG).

Sorry it seems that the file is too big, I''ll mail it to you if you wish

Br

luc

as Gary said in reality there is very little to gain in weight with the length of the bottom halves (lower girdles). If weight is that critical in a particular stone (eg. Risking a 0.99 instead of a 1.00 ct) the cutter would be better off to cut the halves say 9.5 degrees away from the pavilion (instead of 11.25), H&A would then be out of the question, but would probably still get a better price without certification.

Although stones are blocked on the pavilions, in these ‘super cuts’, while finishing halves are cut first.

I’ll ad a few pages out of my training manual (not aimed at H&A), here the halves are 80%, as is usually used in smaller goods (VG).

Sorry it seems that the file is too big, I''ll mail it to you if you wish

Br

luc

JohnQuixote

Ideal_Rock

- Joined

- Sep 9, 2004

- Messages

- 5,212

Luc,

Got it. That percentage jives with my understanding about halves.

In the big picture my impression is that for large cutting houses even the slightest weight recovery is considered, especially with modern tools and measures. Take a smalls manufacturer who saves even 0.01 per carat of goods produced due to such minor adjustments. If he produces 10,000 carats per year he’s recovered 100 carats. At $600 per, he''s gained $60,000 that would have been wasted if he didn''t make that decision. In a factory producing 100,000 carats per year that’s $600,000. However, as Garry said, manufacturers are becoming aware of the need for better cut. Times change.

Thanks for your cutting description... I see now where my understanding differs. What you say makes sense - especially with semi-automatic machines that block in 16 - but that''s not the process that we follow on larger diamonds, say anything above .30. Brian has said that blocking in 16 works quite well in the faceter’s world of colored stones, but we’re still following a traditional method of blocking and brillianteering with our goods- mainly because of graining which Brian is very sensitive to because of facet yaw.

I look forward to getting the manual! Thanks for that, and thanks for being my ‘surrogate cutter’ today

Got it. That percentage jives with my understanding about halves.

In the big picture my impression is that for large cutting houses even the slightest weight recovery is considered, especially with modern tools and measures. Take a smalls manufacturer who saves even 0.01 per carat of goods produced due to such minor adjustments. If he produces 10,000 carats per year he’s recovered 100 carats. At $600 per, he''s gained $60,000 that would have been wasted if he didn''t make that decision. In a factory producing 100,000 carats per year that’s $600,000. However, as Garry said, manufacturers are becoming aware of the need for better cut. Times change.

Thanks for your cutting description... I see now where my understanding differs. What you say makes sense - especially with semi-automatic machines that block in 16 - but that''s not the process that we follow on larger diamonds, say anything above .30. Brian has said that blocking in 16 works quite well in the faceter’s world of colored stones, but we’re still following a traditional method of blocking and brillianteering with our goods- mainly because of graining which Brian is very sensitive to because of facet yaw.

I look forward to getting the manual! Thanks for that, and thanks for being my ‘surrogate cutter’ today

mkb

Rough_Rock

- Joined

- Jul 1, 2005

- Messages

- 47

John,

interesting point about the graining, I would very much like to discuss that with Brian.

I know that in the traditional -big stone- centers (Antwerp, NY, Amsterdam, Tel Aviv) the ''old'' (no offence meant) way is still being followed, I was trained that way too. But as you partly stated, in smaller goods even for H&A the need for production is already taking the front seat.

On the little ''swindling'' to gain these extra few ''points'', garry is right. Manufacturers are paying more attention to the cut now, question of otherwise not being able to sell your goods. If one has a large production, nowadays one is better off being a banker

.

.

Looking forward to the discussion with you and Brian.

TYVM

luc

interesting point about the graining, I would very much like to discuss that with Brian.

I know that in the traditional -big stone- centers (Antwerp, NY, Amsterdam, Tel Aviv) the ''old'' (no offence meant) way is still being followed, I was trained that way too. But as you partly stated, in smaller goods even for H&A the need for production is already taking the front seat.

On the little ''swindling'' to gain these extra few ''points'', garry is right. Manufacturers are paying more attention to the cut now, question of otherwise not being able to sell your goods. If one has a large production, nowadays one is better off being a banker

Looking forward to the discussion with you and Brian.

TYVM

luc

JohnQuixote

Ideal_Rock

- Joined

- Sep 9, 2004

- Messages

- 5,212

Luc,Date: 8/9/2005 12:59:12 AM

Author: mkb

John,

interesting point about the graining, I would very much like to discuss that with Brian.

I know that in the traditional -big stone- centers (Antwerp, NY, Amsterdam, Tel Aviv) the 'old' (no offence meant) way is still being followed, I was trained that way too. But as you partly stated, in smaller goods even for H&A the need for production is already taking the front seat.

On the little 'swindling' to gain these extra few 'points', garry is right. Manufacturers are paying more attention to the cut now, question of otherwise not being able to sell your goods. If one has a large production, nowadays one is better off being a banker.

Looking forward to the discussion with you and Brian.

TYVM

luc

Well, Garry is the most world-travelingest cut nut ever, so he'd know. I understand his frequent flier miles are counted in parsecs now, and instead of a passport he just flashes his ideal-scope and pocket CZs.

No offense at all regarding the 'old' way. Brian prefers it, and I know he'd be delighted to visit with you about graining & yaw.

- Joined

- Aug 15, 2000

- Messages

- 18,484

Nice insights guys.

John an easy way to understand the LG wieght loss:

the mains are cut first - and once the stone is blocked out with its 8 facets the halves are added.

Now if the halves only run 1/2 way down (50% and very short like the olden days) then less material is removed.

But if you polish them to 99%, then you take away more stuff.

But as we know - there are more lower girdles around that are too long - so any theory about cutters deliberately adding weight is plain wrong.

And using 80% as a yard stick - 10% variation either side only results in 0.5% weight variation. As Luc says, selling goods is more important than trying to dud people who will not like your stones because they look too dark with 70% LG''s

John an easy way to understand the LG wieght loss:

the mains are cut first - and once the stone is blocked out with its 8 facets the halves are added.

Now if the halves only run 1/2 way down (50% and very short like the olden days) then less material is removed.

But if you polish them to 99%, then you take away more stuff.

But as we know - there are more lower girdles around that are too long - so any theory about cutters deliberately adding weight is plain wrong.

And using 80% as a yard stick - 10% variation either side only results in 0.5% weight variation. As Luc says, selling goods is more important than trying to dud people who will not like your stones because they look too dark with 70% LG''s

- Status

- Not open for further replies. Please create a new topic or request for this thread to be opened.

Celebrating Mothers And Mentors This Mother's Day Celebrating Mothers And Mentors This Mother's Day - 05/05

Celebrating Mothers And Mentors This Mother's Day - 05/05

Did You Miss the April 2024 Jewels of the Weeks?

Did You Miss the April 2024 Jewels of the Weeks? - 04/26

Did You Miss The Throwback Thursdays For April 2024?

Did You Miss The Throwback Thursdays For April 2024? - 04/25

300x240.png)