- Joined

- Aug 15, 2000

- Messages

- 18,484

News from India

In one of the offices I visited today I found this AGS chart on the wall.

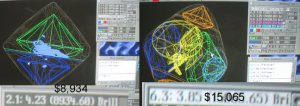

I have been studying Sergey’s latest developments in Helium Rough – the version for planning cutting that looks into the stone and automatically plots the size and position of the inclusions. It seems Sarin is about to release their version, which will be interesting since Sergey has a European and Indian patent.

His patent is here on page 105 of 217

http://www.patentoffice.nic.in/ipr/patent/journal_archieve/pat_arch_072005/official_journal_22072005.pdf

300x240.png)