Kickskid21

Rough_Rock

- Joined

- Jun 23, 2020

- Messages

- 56

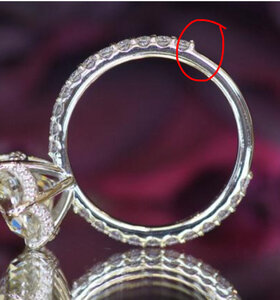

I’m having an engagement ring made by Rhino @ Distinctive Gem and was given 2 options for creating the setting...either have his master bench do it all by hand (more expensive) or have Stuller create it using the cutouts from his CAD (cheaper). Does anybody have any experience/input on this? Thanks!

(here’s the setting for reference https://www.distinctivegem.com/collections/all/products/stephanie)

(here’s the setting for reference https://www.distinctivegem.com/collections/all/products/stephanie)

300x240.png)