T

talamasca

Guest

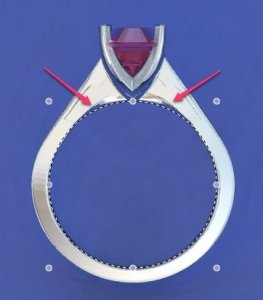

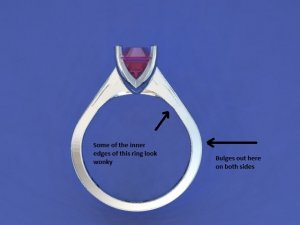

Some of you may remember that I wasn't entirely happy with my e-ring made by a local Jeweller due to it ending up being very thin and the shoulders were weak and not as I had wanted them to be, so I've sent it to DanielM for a re-make and here are the CAD's.

It's defintely thicker - now 2mm tapering to 1mm flat band (previous was 2mm tapering to 0.5mm or less!) and the shoulders are higher, but for some reason I'm hesitating...... it may just be that I'm nervous because of the first experience, but your thoughts/comments would be great. Oh, I've asked if they can send a side view as well.

It's defintely thicker - now 2mm tapering to 1mm flat band (previous was 2mm tapering to 0.5mm or less!) and the shoulders are higher, but for some reason I'm hesitating...... it may just be that I'm nervous because of the first experience, but your thoughts/comments would be great. Oh, I've asked if they can send a side view as well.

300x240.png)