I know a homemade engagement ring has been done in the past, but the idea of walking into a jewelry store and buying an engagement ring just does not excite me. So, that being said... I have done some research over the past few months and I am going to try my hand at some garage investment casting.

I figure this is a great place to document the process and get constructive feedback, so lets get started...

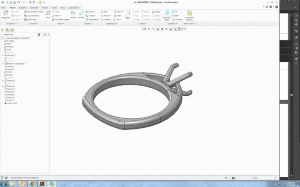

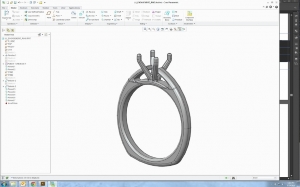

I started with some sketching (a lot of sketching) and then moved into CAD. This took a lot longer than I had expected. Hopefully this will not be indicative of the entire project. I was forcing myself to learn a new CAD software rather than using what I am most proficient with but all in all it was a fun and worthwhile experience.

but all in all it was a fun and worthwhile experience.

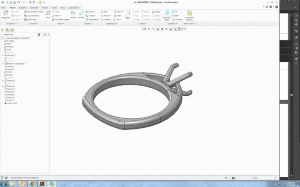

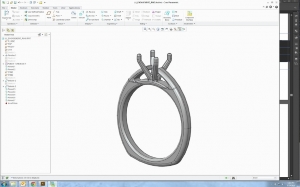

Here are a few photos of the CAD models

Once I had something I was happy with, I pumped out a couple RP parts from a Zcorp printer, purrrrty cool.

The detail in these prints is not spectacular, but I wanted to get a better feel for scale and fit since I am obviously not qualified to do something like this

If anyone has any comments or suggestions, feel free to chime in!

Thanks,

Jovid

I figure this is a great place to document the process and get constructive feedback, so lets get started...

I started with some sketching (a lot of sketching) and then moved into CAD. This took a lot longer than I had expected. Hopefully this will not be indicative of the entire project. I was forcing myself to learn a new CAD software rather than using what I am most proficient with

Here are a few photos of the CAD models

Once I had something I was happy with, I pumped out a couple RP parts from a Zcorp printer, purrrrty cool.

The detail in these prints is not spectacular, but I wanted to get a better feel for scale and fit since I am obviously not qualified to do something like this

If anyone has any comments or suggestions, feel free to chime in!

Thanks,

Jovid

300x240.png)