ChunkyCushionLover

Ideal_Rock

- Joined

- Jun 21, 2009

- Messages

- 2,463

Dear All,

Could someone please explain to me the limitations of the CAD designed wax.

On one hand a local jeweler showed me a hand wax and a CAD wax and discussed how even and precise the CAD wax was. He told me you get much more even detailed precise work with a computer and showed me the differences in the waxes. He also said you have to get a high end setter to place the stones and to finish the piece but that he preferred working with the CAD and even high end rings are most often done this way now.

On the other hand there is no doubt that Leon Mege has done beautiful delicate pieces and I''ve heard he doesn''t even use a wax.

----------------------------------------------

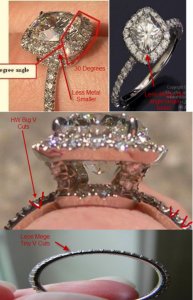

Two of the major issues are with the size and angle of the bezel in the halo and the pave work in both the halo and shank.,

I am referring the following two points:

1) HW halo has less metal than the Leon Mege 811 adrianna and makes a 30 degree angle with the girdle of the stone.

2) The pave work of leon mege I prefer over any other that I have seen his mushroom pave or v cut pave seems to be the most delicate and refined I have seen.

---------------------------------------------------

Questions:

1) Can other jewelers using a CAD produce similar pave with smaller v cuts if you are specifc with them?

2) What are the limitations with the CAD wax and can you do as refined and delicate work?

3) Is the difference not in the wax and structural design but in the setting of the stones and the finishing work?

---------------------------

I look forward to any responses people may have.

300x240.png)