- Joined

- Aug 15, 2000

- Messages

- 18,459

It seems that the current release of GemAdviser is not able to read properly Brilliant cuts with extra parameters that were introduced in the beta of DiamCalc. This issue will be fixed and two programs will be synchronized when the full DiamCalc2.4 is released.

Date: 5/19/2006 5:10:27 PM

Author: Rhino

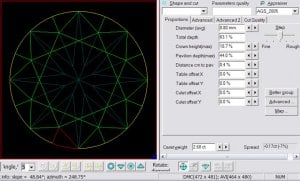

This is the profile of the example you had given which was confusing some folk.

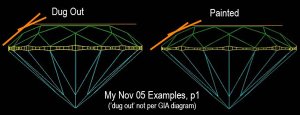

The example Garry provided is an example of some extreme digging. We see this alot on common commercial stuff. Please dont' take my criticism in the wrong spirit John. Just trying to help.

Kind regards,

The additions are good. Thank you, Rhino.Date: 5/19/2006 5:24:06 PM

Author: Rhino

Here's of the painted (similar to your example). BTW I like how you compiled the data John. Good job.

One challenge in trying to represent this is that the rules are limitless in reality, but more limiting and subject to nature's whims at the wheel. It's not possible with a real diamond to adjust a wire frame thicker or thinner like anyone can do in software. On the wheel you can only adjust angles (steep or flat) or cheat (left to right). Even knowing this, most people don't understand the way a facet runs on the wheel.Date: 5/22/2006 4:38:05 PM

Author: He Scores

Painting and digging are not products of just a girdle facets angle. The STRAIGHTNESS of that particular facet is just as important when the cutter makes an adjustment to the facet. In fact, at a certain point in it's size a brilliandeering facet cannot be 'dug' simply by increasing the angle without dire consequences like missing the midpoint in the main facet. It's interesting that many performance models assume that facets are straight with each other when trying to determine the direction of light (Ray Tracing) just as one angle of main is used from the averages of all. Major differences can occur in all the cases.

Understood. I previously said:Also John, just for your edification, the direction in which a facet is polished (read aligned with the wheel) has no primary and direct relationship with the angle the facet is made on. This alignment is dictated by the granular structure of the diamond and MAY however, be influenced by angle but not in every case.

The diagrams were created to give understanding to the average person: For instance, in order for the diamond to be polished we gave an example of painting from star to girdle...In reality it may still be taken from the girdle side, but because the angle is so flat and so little material is taken from the girdle, the simplified drawing was to demonstrate the principal.Date: 5/21/2006 8:35:45 PM

Author: JohnQuixote

Back when this thread was posted it was to illustrate techniques of cutters, using simple examples to help average people understand steep vs. flat. We were not using girdle profiles to identify the stone, just showing how a diamond cutter digs and paints (those polish diagrams are simplified as well).

I will give you hallelujah.

This is pretty ecclisiastical, so I'll stop. However, I think all you 'cut nuts' should take time out and sit at the wheel with a cutter and learn how to cut. It can only add to your already broad understanding of workmanship.

Bill Bray

Diamond Cutter

Painting and performance qualities: I believe this is impacted by distance to the diamond as well as the optical symmetry. Within robust proportions sets painting can maximize beauty. It may or may not even be visually distinguishable from non-painting; as must be reiterated, it depends on how much. It is possible to over-paint, and it’s possible to do this with traditional brillianteering too. Too much painting results in less definition of the bezel facets. The opposite is going too far in the traditional manner (digging), which can result in performance issues or even a knife-edge girdle. In either situation, when quality control is present, the diamond can be beautiful. It all boils down to the quality and care of the manufacturer handling the stone.Date: 5/22/2006 4:38:05 PM

Author: He Scores

The face up view that has been marketed heavily by some manufactures of 'premium' cut stones should not be the end all for what a diamond looks like. While pasting top halves may allow for less light leakage when viewed in one particular position, it cuts down on the definition between the mains and themselves(like John appropriately pointed out) and this makes for a lack of what I call 'scintillation' or the reflection of light off the facet surfaces (or whatever the hot topic name for it is in the labs). In addition to that, to some there is beauty in a straight and even girdle all around rather than thinner or thicker at the point under the halves. On the other hand, 'digging' even slightly reduces the angle between each half in a set with a similar reduction of facet reflection.

The Tolkowsky Model is a compromise between all of the above factors, including the face up appearance and that's why I think it will always have a larger market share than just the performance stones.